what’s the 360° turning industrial endoscope?

An industrial endoscope is an inspection tool equipped with optical components. It is use to inspect areas and small spaces that cannot be visualize. The inspection tool has a handheld main body. The central unit is connect to a long insertion tube with a camera and 360° steerable. For example, we can insert long lines of industrial endoscopes into engines. The engine can be inspect without taking it apart. Technical service personnel can use this tool. Look for signs of cracks, corrosion and general wear inside complex assemblies. Endoscope with measuring function. Except looking for cracks etc. The length of the crack can also be measure. Corroded area. depth of damage, etc. It can provide reference for technicians to overhaul.

Industrial endoscopes can save maintenance personnel time and cost in performing routine inspections. The lines of these endoscopes come in different sizes and styles. They are design for different uses. The most common applications are on turbine engines, piping systems, and automotive engines.

Industrial endoscopes consist of several vital components.

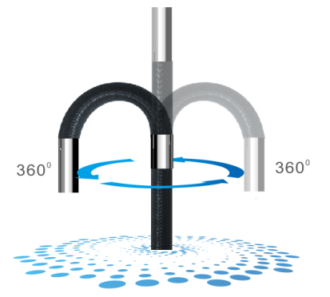

These include a central unit with a high-definition LCD screen. controls, a four-layer tungsten-woven, abrasion-resistant insertion tube, and a high-definition camera. The head unit features zoom. playback, video and photo capture, and joysticks for steering. At the end of the insertion tube is the camera. It can do full 360-degree steering in all four directions. The camera at the end of the insertion tube is equipped with many LED lights. The surroundings are illuminate for optimal visualization. After taking photos and videos.

Users can remove the SD card from the main unit. Download the content to their own device for further analysis. Insertion tubes are available in different lengths and diameters. There are also cameras in different orientations. For example side-view mirrors, direct-view mirrors, endoscopes with dual lenses. The side and front of the object to be inspect can be observe . It can observe the inspected object more and save time.

Insert the endoscope line into a device or space to inspect. such as an engine, and make a 360° turn depending on the actual situation to detect signs of damage or wear. The long insertion tube is ideal for reaching deep into the device under inspection. Complete inspection of the piping system. During the inspection, the technician can take pictures. Record live video for later viewing. Many endoscopes can also record sound. So videos can have voiceovers for real-time inspection analysis.

Yateks M series industrial endoscope. It supports 360° mechanical, arbitrary steering, and 180° bending. This product is cost-effective. The market has recognized it for many years.