1.Material Performance

In environments characterized by extreme high temperatures, the material performance of industrial borescopes undergoes rigorous scrutiny. Traditional materials utilized in borescopes may soften or deform under such conditions. For instance, conventional plastic components can lose their integrity, softening and failing to retain their original shape and mechanical strength. This deterioration compromises the outer shell’s ability to safeguard the internal optical and electronic components, thereby adversely affecting the device’s operational efficacy. Research indicates that the typical operating temperature range for standard industrial borescope hosts is between -20°C and 60°C, with probes operating between -20°C and 85°C. Should temperatures exceed these parameters, the material properties may significantly decline. Additionally, elevated temperatures can adversely impact the chemical stability of materials. Certain metallic components may undergo oxidation at high temperatures, leading to rust or corrosion on their surfaces. This degradation not only affects the borescope’s aesthetic appeal but, more crucially, jeopardizes its internal precision structure. For instance, corrosion of the optical lens coating can severely impair imaging quality.

2.The Impact of Extremely High Temperatures on the Optical System

The optical systems within industrial borescopes also confront numerous challenges in the face of extreme heat. Thermal expansion and contraction may alter the shape and positional relationships of optical lenses and their components. Even slight lens deformations can result in imprecise light focusing and blurred images. In high-temperature environments, even minuscule changes in dimensions can profoundly impact the optical system’s imaging performance. Furthermore, elevated temperatures can alter the refractive indices of optical materials. Different materials exhibit varying refractive indices at distinct temperatures. An increase in temperature leads to changes in the refractive index, consequently modifying the light’s propagation path and affecting image clarity and accuracy. This presents a significant challenge for industrial borescopes that require precise observation of internal structures.

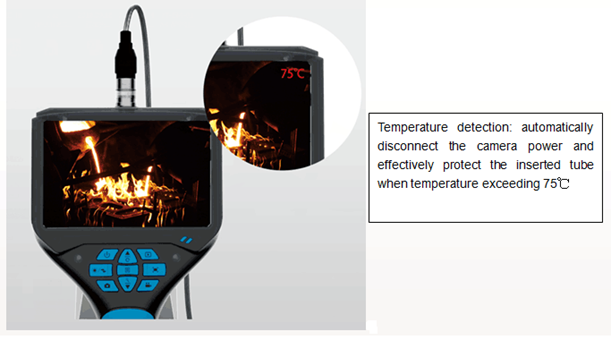

3.Electronic Components and Imaging

The electronic components within borescopes display heightened sensitivity to temperature variations. Extreme heat can result in the degradation or even failure of these components. For example, elevated temperatures can alter the resistance of electronic components, disrupting normal circuit operations. This disruption may prevent image sensors from capturing images effectively, resulting in issues such as noise, signal loss, or other anomalies in the acquired images. In terms of imaging quality, thermal noise generated in high-temperature environments can interfere with image signals, manifesting as random bright spots or noise that diminishes overall image quality. Moreover, as temperatures rise, the power consumption of electronic components may escalate, adversely impacting battery life in portable borescopes and potentially triggering protective mechanisms that halt functionality due to overheating.

4.Borescope Equipment Service Life

Prolonged exposure to extremely high temperatures can significantly truncate the service life of an industrial borescope. The aging rate of materials is markedly accelerated; whether it pertains to the housing, optical components, or internal electronics, the degradation occurs at a pace much faster than in a typical temperature environment due to sustained high-temperature exposure. For instance, rubber seals may become hardened and brittle, rapidly losing their sealing capabilities, thereby permitting dust and moisture ingress that further compromises the equipment. Additionally, frequent thermal shocks—such as abrupt transitions from normal to high-temperature environments and vice versa—can induce thermal stress within the device. This stress gradually accumulates, leading to issues such as loose solder joints and circuit board fractures, ultimately rendering the industrial borescope inoperable.

The ramifications of extreme high temperatures on industrial borescopes are multifaceted, affecting material properties, optical systems, electronic components, and overall equipment longevity. This reality has driven technicians to persistently develop innovative high-temperature-resistant materials, optimized designs, and advanced heat dissipation technologies to enhance the performance and reliability of industrial borescopes under extreme conditions.