Are you troubled by the inability to accurately locate the details you want to watch carefully when using the endoscope?

Do you feel troubled when using the endoscope because the color of the picture is not reproduced enough?

Do you feel tired when holding the endoscope because the body of the endoscope is too heavy?

Are you troubled because the brightness of the endoscope is not enough to see more details?

The role of non-destructive testing technology in the quality assurance system is becoming more and more important. It has become an important means to control product quality and ensure the safe operation of equipment. If you want to do non-destructive testing, the accuracy of the test results is very important.

Generally speaking, we analyze the factors that affect the accuracy of the test results through the two most common aspects

The first aspect: the performance of testing equipment

As the first factor, the performance of the detection instrument, for the endoscope, the most important performance is whether the diameter of the lens is appropriate, whether it can smoothly penetrate into the working channel, whether the length of the insertion tube is sufficient, and whether it can be smooth Through the entire space that needs to be inspected, whether the resolution of the lens is sufficient, whether the small cracks can be seen smoothly, whether the brightness of the lens is enough, and whether the various details in the pipeline can be clearly seen in a sufficiently dark environment .

The second aspect: human factors

As the second factor, it is the operating level and professional knowledge level of the inspection personnel. Therefore, it is very important to conduct professional training for the non-destructive testing personnel, and conduct a comprehensive assessment after the training. In this way, we will get a accurately and highly reliable test result.

Based on the two factors analyzed above, the M-ADV series industrial borescope of Yateks can well meet all the above needs!

Yateks’ M-ADV series industrial borescope has a flexible bending section: mechanical rotation for 360º and bend for 160º—convenient, accurate, and automatic reset.

Even in complex pipelines or working conditions, M-ADV series’s flexible insertion tube can complete the operation extremely accurately.

Make sure not to miss the details you want to observe.

The M-ADV series industrial borescope is controlled by a mechanical joystick, and the probe has 4 built-in steel wires that can be accurately positioned to the part that needs to be detected. Just like the four fingers of a human, it can be flexibly bent to any angle.

The M-ADV series has a variety of models for customers to choose from. The lens diameter can reach an extremely thin 2.2mm, and there is also a versatile 6mm. The insertion tube length can be selected from 1-10 meters. For complex internal environments, M- The ADV series is also equipped with dual lenses, and the same high-resolution side view camera can help customers check any details inside.

M-ADV series uses a powerful mechanical joystick, which has undergone strict quality inspection and durability testing to ensure that it can continue to maintain accuracy even under high-intensity repeated use.

Electromagnetic joystick has certain limitations in its operating range because of its design principle.The mechanical joystick can be controlled at will according to your own ideas and perform very fine control.

And there is no noise when using the mechanical joystick, but the electromagnetic joystick will have the sound of the motor starting.

The base unit of the M-ADV series is only 0.75KG, which is very light. Even if it is held for a long time, the hand will not feel very tired. The handle part of the base unit is designed with ergonomics, so customers can have a very comfortable hand-held feeling when using it. The M-ADV series is well realized: a portable endoscope that can be held in one hand.

M-ADV series’s software is powerful and easy to operate, even customers who use endoscopes for the first time can use the M-ADV series well in a short time. such as automatic white balance, especially when checking different rusty metals. With the help of automatic white balance, the color of the image is very close to the color actually seen by the human eye.

Therefore, the user can intuitively see the degree of metal rust, which has a very practical reference value for evaluating the status of equipment and parts.

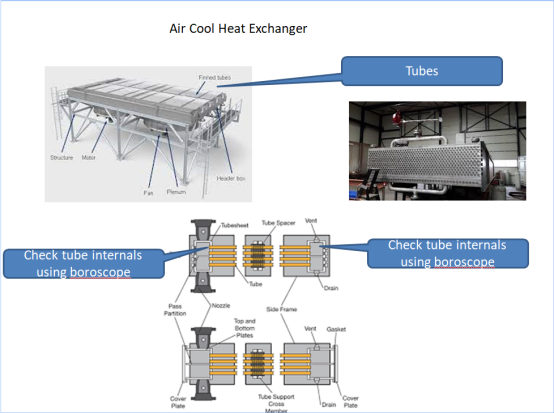

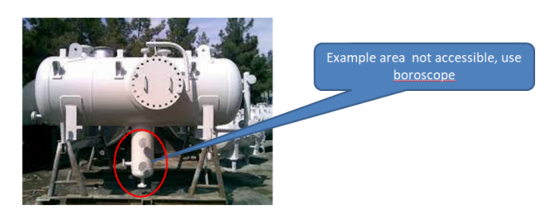

Finally, there is an actual case of using M-ADV to detect Air Cool Heat Exchanger. The end user is a very well-known industrial service provider in Norway. Please refer to the following picture for details. We need to use the M-ADV series to view the inside of the Air Cool Heat Exchanger

We can see from the picture that the internal structure of this device is very complicated, and customers can detect each part in detail by using the flexible bending section of M-ADV.

The end customer can manipulate the M-ADV series well after learning the operation manual of the M-ADV series even if he has never used any endoscope products before.

After using M-ADV to detect Air Cool Heat Exchanger, whether in terms of operability, functionality, or price, etc, customers are very satisfied with our products.