In the fast-paced world of manufacturing, precision and efficiency are paramount. Companies are constantly seeking innovative solutions to streamline their inspection processes while maintaining the highest standards of quality. Enter industrial borescopes – the game-changer that is revolutionizing inspection processes across the manufacturing industry.

1.Introduction to Industrial Borescopes in Manufacturing

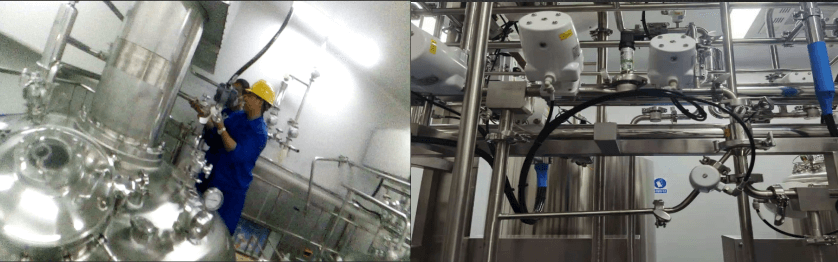

Industrial borescopes are cutting-edge tools that offer a glimpse into the hidden world of machinery and equipment. These versatile devices, equipped with high-definition cameras and flexible probes, enable inspectors to access and visualize hard-to-reach areas with unparalleled clarity and detail. By providing real-time images and videos of internal components, industrial borescopes empower inspectors to identify defects, abnormalities, and wear and tear that may not be visible to the naked eye.

2.Benefits of Industrial Borescopes

(1)Saving time and resources through non-destructive testing

One of the key advantages of industrial borescopes is their ability to save time and resources. Traditional inspection methods often involve dismantling machinery or equipment for a thorough assessment, leading to costly downtime and labor-intensive processes. With industrial borescopes, inspectors can perform non-destructive testing quickly and efficiently, minimizing disruptions to production schedules and reducing operational costs.

(2)Enhancing quality control and ensuring compliance with industry standards

Moreover, industrial borescopes play a critical role in enhancing quality control and ensuring compliance with industry standards. By enabling inspectors to conduct thorough visual inspections of critical components, industrial borescopes help identify issues early on, preventing potential malfunctions and ensuring product quality and safety.

(3)Real-time visualization of internal components for early defect detection

The impact of industrial borescopes extends beyond manufacturing facilities. These advanced inspection tools are also utilized in various industries, including automotive, aerospace, energy, and more. From inspecting aircraft engines and pipelines to examining automotive components and industrial machinery, industrial borescopes have become indispensable in maintaining the integrity and reliability of critical systems and equipment.

As technology continues to evolve, industrial borescopes are poised to drive further advancements in inspection processes, offering unparalleled precision, efficiency, and reliability. By investing in industrial borescope technology, manufacturers can stay ahead of the curve, optimize their inspection processes, and ensure the highest standards of quality and safety in their operations.

3.Conclusion: Embracing Industrial Borescopes for Manufacturing Excellence

In conclusion, industrial borescopes are not just tools; they are catalysts for innovation and progress in the manufacturing industry. With their ability to provide a detailed view of internal components, streamline inspection processes, and enhance quality control, industrial borescopes are shaping the future of manufacturing inspection. Embrace the power of industrial borescopes and elevate your inspection processes to new heights of efficiency and excellence.