More and more industries use industrial endoscopes. For example, aerospace, mechanical casting, auto parts manufacturing inspection, pipelines, and welding inspections. The topic I’m going to discuss today is pipe weld inspection camera.

Pipe weld inspection camera plays an important role in the inspection of welds

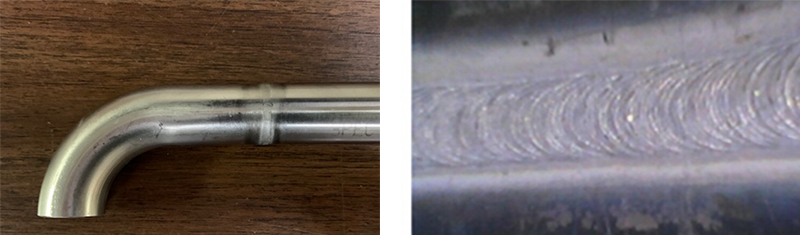

The quality of the weld has an essential influence on the quality of the fluid transported by the pipeline. Standard welds need to be welded on one side, and then both sides need to be formed. There should be no false or missing welds, and the color of the weld will not turn yellow or black. Therefore, it is necessary to use pipe weld inspection camera to check the weld conformity

The weld seam and the surface of the stainless steel pipe look the same through the grinding process. On this occasion, Using pipe weld inspection camera to detect the welds is a wise choice. Video oscilloscope can take pictures and videos. It can also view the color and shape of the weld quality in real-time. Pipe weld inspection camera has an essential application in the inspection of stainless steel pipe welding. There may be false welding, welding slag, etc., without this inspection, which will hinder fluid transfer. There is liquid in the gap between the welds. This will breed bacteria for a long time and affect the overall quality of the liquid.

How to use pipe weld inspection camera

How to observe and inspect the weld quality with the help of pipe weld inspection camera? The most common way is to use an industrial Borescope/Videoscope. But not all weld inspection cameras are suitable. There are many different specs and brands on the market. You need to choose the right one according to your actual application. You can judge from the following aspects.

1.Lighting conditions.

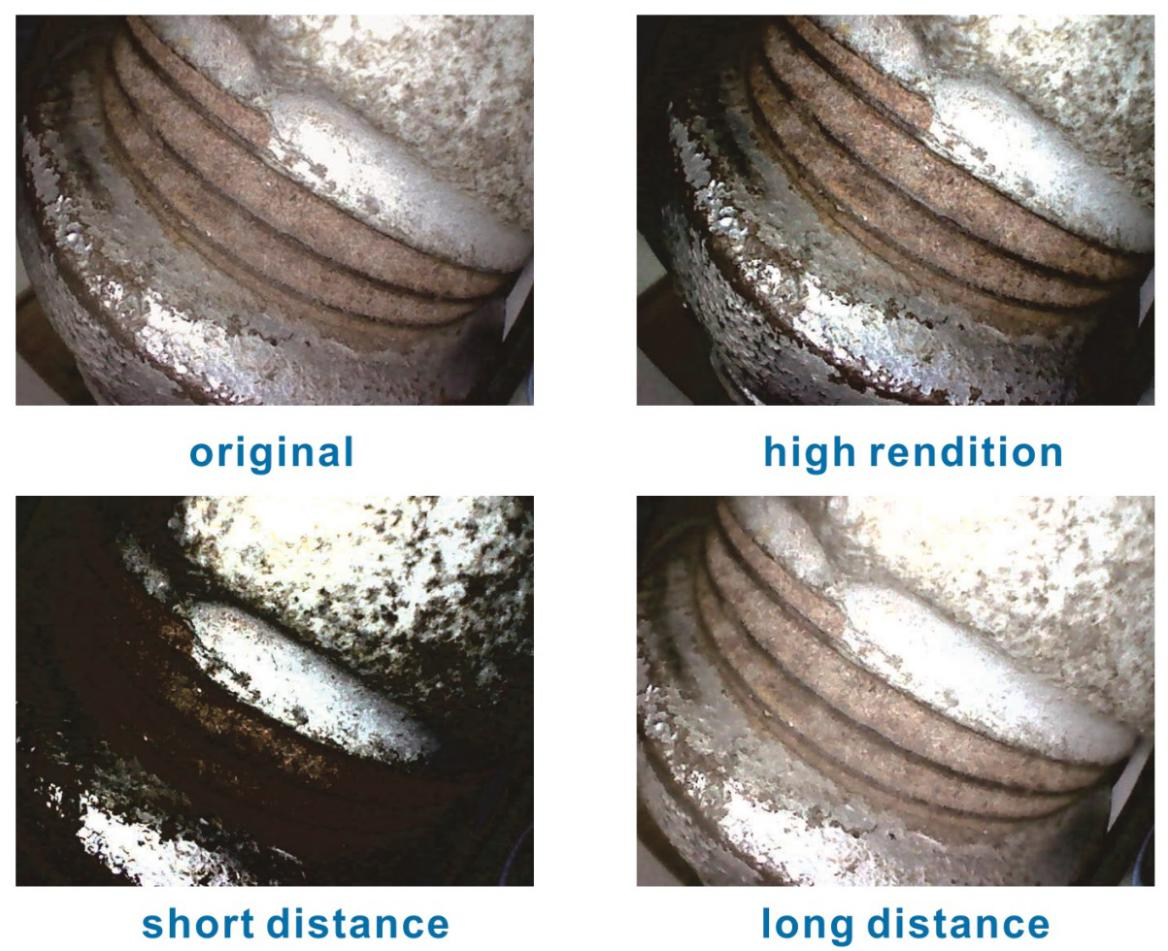

Videoscope detection mainly uses the borescopes’ light source for illumination, LED or Fiber light. It is not that the brighter, the better. Some stainless steel surfaces will reflect and expose when encountering intense light, so you must choose the right light source before using the pipe weld inspection camera.

2.Probe position and bending angle.

Usually, it’s better to observe the image within the range of 5~25mm from the detection area. So the pipe weld inspection camera must be as close to the observation position as possible. The search and the observation object plane can achieve better observation results in the range of 45゜~90゜. In actual work, finding a suitable observation position by repeatedly changing the part and angle of the probe and the observation point and obtain the best detection effect.

3.Tube.

When selecting a Tube for inspection, it should detect as close as possible to the location and choose the channel with the shortest length to minimize the number and degree of bending of the probe. Firstly, you can consider the track from top to bottom, from high to low. I prefer the wider channel, First consider the passage from top to bottom, from high to low, as the wide passage. It is recommended to use tools to ensure that the pipe weld inspection camera is in the correct direction in the channel. Try to use the method of observing and passing in the Chanel.

4.Diameter and Length

You need to choose a suitable pipe weld inspection camera size according to the tube, choose the exact length and diameter. For example, if the diameter of your pipe is 1” around, you need to select a Borescope with a 6mm probe. You need to keep enough space for the investigation to move freely in the tube.

The advantage of our pipe weld inspection camera

To inspect stainless steel pipe welds and other aspects, Yateks launch P Series Industrial Videoscopes, which feature a large 8″ monitor that can utilize in the field or a desktop inspection environment with the available HDMI output to an external display. The display is super clear, and the color of the internal welds of the pipeline is not distorted. The operation is flexible and can inspect the inner wall of the steel pipe in all directions. In detection, pipe weld inspection camera can partially digitally enlarge the observation effect. According to the stainless steel of different diameters, can adjust the light to avoid the reflection of the stainless steel pipe. Can control a detachable probe with electronic, magnetic rocker omnidirectionally for 360°.

For the special occasions of welding seams on the inner wall of stainless steel pipes, Yateks also launched a series of cost-effective side-view industrial Borescope with instant light supplement function, which is very suitable for places with poor light such as the inside of the pipe; and anti-reflection, even if the metal inner wall is smooth, also can be seen clearly. The length of the pipe weld inspection camera can be as long as 20 meters.

Conclusion

Yateks industrial Borescope has been widely recognized as a well-known brand and applied for stainless steel inner wall weld inspection, pipeline inspection, wind power inspection, nuclear power inspection, engine inspection and maintenance, and archaeology. To learn more about our products, please visit our website www.yateks.com.