Imagine this: A massive cement mill grinds to a sudden halt, paralyzing the entire production line. After a frantic investigation, the root cause is pinpointed—a hidden bearing deep inside the gearbox. But traditional inspection means days of disassembly, with staggering production losses looming.

In the demanding environment of cement production, gearboxes are the powerhouse, driving core equipment like mills, crushers, and fans. Operating under extreme conditions—intense heat, heavy dust, and relentless load—their internal gears, bearings, and seals are under constant assault. The cost of unplanned downtime is more than you think:

-

Massive Financial Loss: Production halts, orders are delayed—every second costs money.

-

Disassembly Risks: Traditional “open-up” inspections are time-consuming, labor-intensive, and risk causing secondary damage or assembly errors.

-

Lurking Threats: Tiny cracks and early-stage wear are invisible to the naked eye, often leading to catastrophic failure.

What’s the solution? The Industrial Endoscope—your specialized, “non-destructive, visual” inspection expert for cement plant gearboxes!

Simply insert the endoscope’s agile probe through an inspection or oil port. Like a minimally invasive surgical tool, it navigates deep inside the equipment, transmitting real-time, high-definition video of critical areas—gear teeth, bearing races, and seals—directly to your screen. No more guesswork. Total visibility, total control.

Core Value: Industrial Endoscope for Cement Plant Gearboxes

-

Pinpoint & Diagnose Fast: Bypass major teardowns. Quickly locate faults like pitting, spalling, broken teeth, bearing wear, cage damage, or foreign object debris. Drastically reduce downtime.

-

The Ultimate Predictive Maintenance Tool: Conduct regular “health checks.” Identify potential failures—from a 0.1mm crack to minor wear—before they escalate, transforming reactive repairs into proactive prevention.

-

Verify Repair Quality: Post-maintenance, instantly verify internal assembly quality and part replacement, ensuring the job is done right the first time and avoiding rework.

-

Enhance Personnel Safety: Inspect hazardous, confined, or hot spaces without physical entry, ensuring maximum safety for your team.

-

Extend Lifespan & Lower TCO: Reduce unnecessary disassembly, optimize maintenance schedules, and significantly lower your total cost of ownership while boosting equipment reliability.

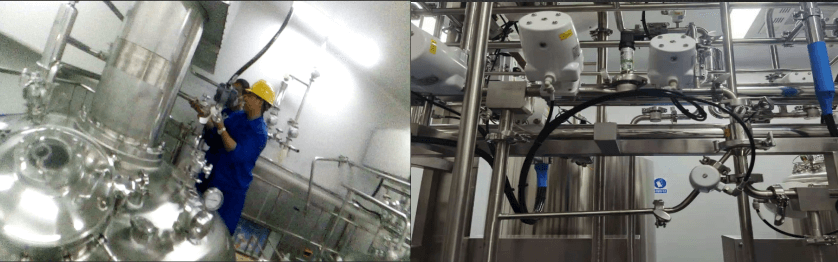

Application in Action: A Cement Plant Case Study

A major cement plant implemented Yateks P-Series HD Video Endoscopes (2MP resolution, 360° articulation) to inspect gear meshing, tooth surface damage, and bearing condition under massive load.

The Results Speak for Themselves:

-

300% Increase in gear wear inspection efficiency.

-

92% Accuracy Rate in early bearing fault detection.

-

Over $1 Million USD Saved Annually in preventive maintenance costs.