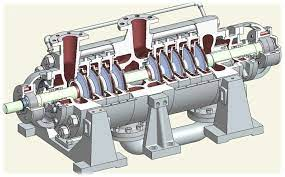

The boiler mainly consists of two parts, the pot and the furnace, and it is an energy conversion device. The input in the boiler is fuel that can be converted into energy, and the output is steam, high-temperature water or organic heat carrier with certain heat energy.

The hot water or steam generated in the boiler can directly provide the required heat energy for industrial production and people’s life. Cocoa can be converted into mechanical energy by a steam power plant. Or convert mechanical energy into electrical energy through a generator. Boilers that provide hot water are called hot water boilers, which are mainly used in daily life, and also have a small amount of application in industrial production. It is mostly used in thermal power stations, ships, locomotives and industrial and mining enterprises.

1.Maintenance purpose

The maintenance and repair of boiler equipment is an important link to ensure the safety and economical operation of boiler equipment and to improve the availability factor of boiler equipment. Management departments at all levels and every maintenance personnel must pay attention to the maintenance work, and implement the principle of “repairs must be repaired, repairs must be completed, prevent disrepair, avoid redundant maintenance, and ensure equipment safety and reliability”. In the maintenance, strictly follow the regulations and program requirements: complete the maintenance tasks with high quality, safety and efficiency, and provide a high-quality material basis for the power plant to improve safety, stability, long-term, full load, and optimize production

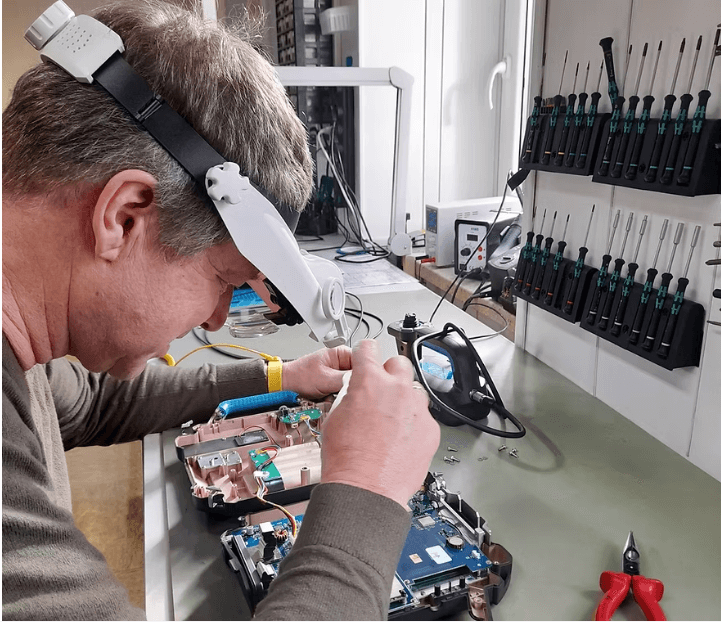

2.Inspection scope and process of industrial pipeline borescope

Water wall maintenance process

- Cleaning of the water wall: cleaning the outer wall of the pipes to clean up the ash and scorched slag

- Check the water-cooled wall tube near the burner, and use an industrial pipeline borescope to detect internal corrosion.

- Replacement and repair of worn, bulging, deformed and damaged pipe sections

- Eliminate defects in operation

Superheater maintenance process

- Heating surface and horizontal flue cleaning

- Check wear, overheating, swelling and creep

- Check, repair and replace pipe clamps, comb plates and anti-wear devices

- Use an industrial pipeline borescope to detect the weld seam inside the pipe and take pictures and videos

- Cut the pipe to check the internal condition of the pipe

- Replace the pipes with individual defects exceeding the standard

Maintenance process of reheater

- Clean the dust on the outer wall of the pipe

- Check the wear, swelling and bending deformation of the pipe

- Clean or repair boiler header support

- Open the hand hole of the boiler header, use an industrial pipeline borescope to check the corrosion and scaling and whether there are foreign objects, and clean the interior according to the content of the shooting