Borescope inspections are an important aspect of industrial maintenance and quality control. It involves using specialized equipment, such as industrial borescope cameras, to visually inspect the interior of machinery, pipes, and other hard-to-reach areas. This article will provide a comprehensive guide to borescope inspection, focusing on the importance of the process, the benefits of using industrial borescope inspection cameras, and the various applications of borescope inspection in different industries.

The importance of borescope inspection

Borescope inspections play a vital role in ensuring the safety, reliability and efficiency of industrial equipment and infrastructure. By allowing inspectors to visually inspect the internal components of machinery and structures, borescope inspections help identify potential problems such as corrosion, cracks, clogs, and other forms of damage that may not be visible from the outside. This proactive approach to maintenance and inspection prevents costly downtime, equipment failures and safety hazards, ultimately helping to increase the overall productivity and longevity of industrial assets.

Benefits of Using Industrial Borescope Inspection Cameras

Using industrial borescope inspection cameras offers several advantages over traditional inspection methods. One of the main benefits is the ability to enter and inspect confined spaces without the need for disassembly or extensive disassembly of the equipment. Not only does this save time and labor, it also minimizes the risk of further damage during the inspection process. In addition, the high-resolution imaging capabilities of modern borescope cameras can provide clear and detailed visuals of internal conditions, allowing inspectors to make accurate assessments and informed decisions regarding maintenance and repairs.

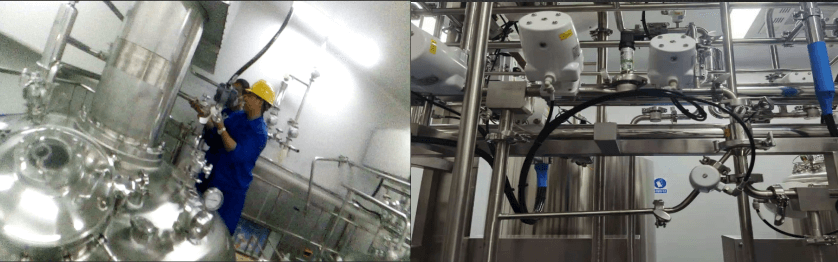

Additionally, industrial borescope inspection cameras are designed to withstand harsh industrial environments, making them suitable for a wide range of applications including manufacturing plants, power generation facilities, aerospace, automotive, and more. Its durable construction and flexible, maneuverable probe enable inspectors to navigate complex systems and capture images and video of otherwise inaccessible areas, ensuring a thorough and comprehensive inspection.

Borescope inspection applications in different industries

Borescope inspections are widely used in various industries for maintenance, quality control and troubleshooting purposes. In the aerospace industry, borescope inspections are critical for inspecting aircraft engines, turbines and other critical components to detect signs of wear, foreign object damage or other defects that could compromise safety and performance. Likewise, in the automotive industry, borescope inspections are used to inspect engine cylinders, fuel systems, and exhaust components to help diagnose mechanical problems and ensure compliance with quality standards.

In manufacturing and industry, borescope inspections are used to evaluate the condition of pipes, heat exchangers, boilers, and other equipment to help identify corrosion, leaks, and structural integrity issues. This proactive maintenance approach prevents costly downtime and production interruptions, ultimately helping to improve operational efficiency and save costs. Additionally, borescope inspections are used in the pharmaceutical and food processing industries to inspect production equipment and facilities to ensure compliance with health and safety regulations.

Best Practices for Borescope Inspections

To maximize the effectiveness of borescope inspections, best practices and guidelines must be followed to conduct a thorough and accurate inspection. Proper training and certification of personnel responsible for borescope inspections is critical to ensuring proficiency in using the equipment and interpreting inspection results. Additionally, industrial borescope cameras require regular maintenance and calibration to maintain their performance and accuracy.

When performing a borescope inspection, it is important to document the inspection results (including images and videos) and keep a detailed record of the inspection for reference and analysis. This documentation can serve as a valuable resource for tracking equipment condition over time, identifying wear and degradation trends, and making informed decisions about maintenance and replacement schedules.

Additionally, adhering to safety protocols and regulations is critical when performing borescope inspections, especially in industrial settings where hazards such as high temperatures, toxic materials, or confined spaces may be present. Inspectors should be equipped with appropriate personal protective equipment and follow established safety procedures to reduce risk and ensure health during the inspection.

Future trends in borescope inspection technology

As technology continues to advance, the field of borescope inspection continues to evolve with the introduction of innovative features and capabilities in industrial borescope cameras. A notable trend is the integration of wireless connectivity and digital imaging technology, allowing inspectors to remotely view and capture inspection data in real-time, thereby enhancing collaboration and decision-making processes.

Additionally, advances in camera resolution, illumination, and probe flexibility are enhancing the overall performance and usability of borescope inspection equipment, allowing inspectors to achieve greater accuracy and efficiency in inspections. Additionally, the integration of augmented reality (AR) and artificial intelligence (AI) technologies is expected to revolutionize borescope inspection by providing automated defect identification, analysis and reporting capabilities, streamlining the inspection process and improving the accuracy of inspection results.

In summary, borescope inspections facilitated by industrial borescope inspection cameras are a critical tool in maintaining the integrity and reliability of industrial equipment and infrastructure. By providing visual inspection of hard-to-reach areas, borescope inspections help identify problems early, proactively maintain and improve safety across industries. As borescope technology continues to advance, the future offers promising opportunities to further improve the efficiency and effectiveness of this basic inspection method.