Author: Nancy Dong

Date: 2019/5/15

Borescope inspection is a visual detecting method for quality control of areas that human eyes can not observe directly, special areas such as vessels, pipe inner part of the non-detachable equipment, the inner surface of pipe gap, liquid surface, etc. Yateks inspection videoscope camera is designed for the non-destructive testing (NDT) of engines, machines and more. So, somebody maybe asking how to choose a borescope or videoscope.

On this question. You need to know these 8 tips before choosing an Industrial Borescope. The exact position of the inspection hole.

This will help you to know the camera direction of view, understand the accessible route and length of insertion tube you will choose.

1. The exact position of the inspection hole.

This will help you to know the camera direction of view, understand the accessible route and length of insertion tube you will choose.

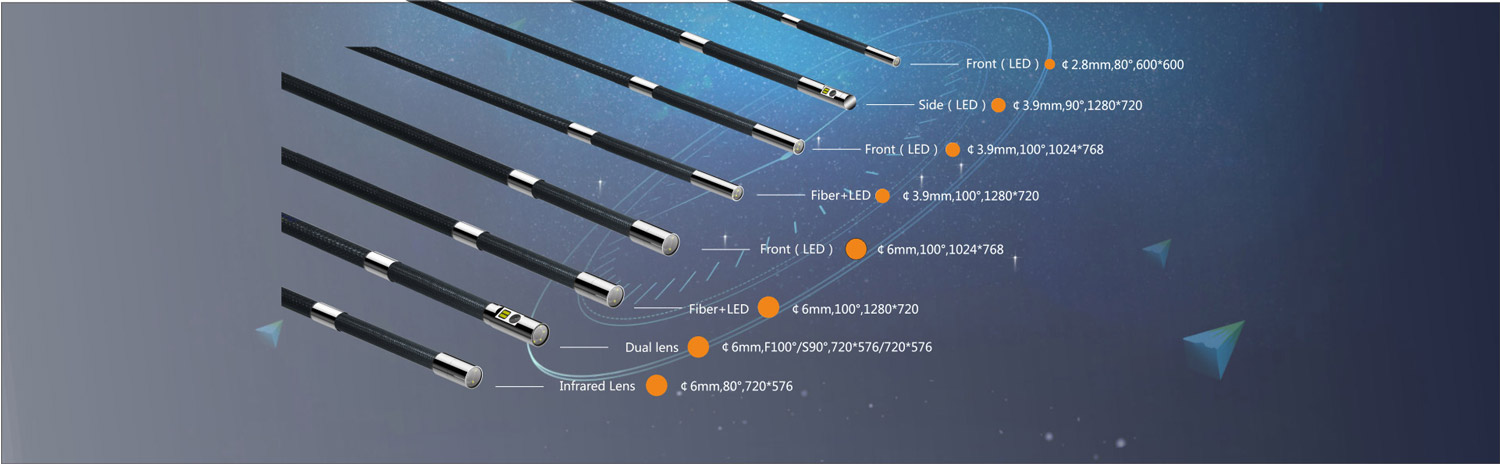

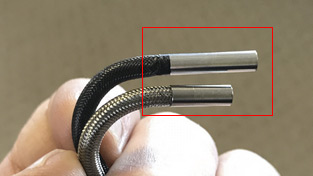

2. The exact size of the inspection hole.

That will help you to decide the diameter you may need, 2.8mm,3.9mm,6mm or 9mm.

3. Outline the size of inspection Objects.

This including the whole size of inspection Objects, size of cracks or distortion, this is the most important factor to decide the angle of view and brightness of light you may need.

4. Defect size.

The size of defects is an important factor to decide the right resolution, magnification times, minimum defects detectable and focus abilities so that you can catch the appropriate and clear images.

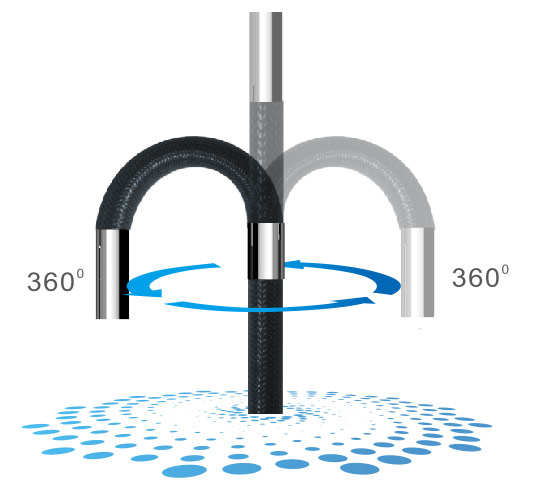

5. Distance and angle from lens to the inspection objects.

The distance from the lens to the inspection objects will affect the illuminating requirements directly no matter you use standards or high-intensity light source, The angel of view will decide whether you need bending or articulating probe, then find the best viewing position to obtain the best image resolution and maximum magnification.

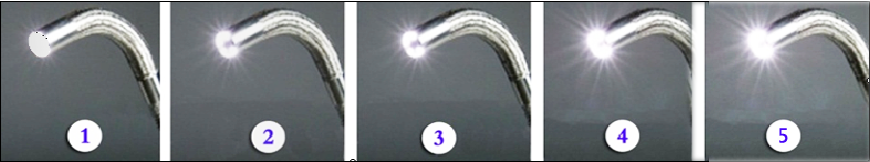

6. The reflectivity of light

The different surface has different reflectivity, depends on the material and roughness of the surface. Therefore, you need to choose suitable illumination according to the specific situation to get the best effect but not the Strongest light source in the actual inspection.

7. The approach path to the inspection point.

A rigid or flexible bending path will decide which kind of insertion tube you may need.

8. Working condition.

You need to consider the temperature, humidity, light and other factors for inspection, choose a good performance model like waterproof, oil proof, corrosion resistance, tough, strong electromagnetic interference or violent voltage fluctuation and explosion proof. So that you can use it in a safe working station.

Hop these tips could help you to choose a suitable Borescopes.

Yateks videoscope adopts megapixel COMS high-definition camera with 8-inch high-quality industrial-grade touch screen, high-definition image restoration effect, the whole machine integrated portable design is lighter, and the detection probe 360° omnidirectional guidance is used for Different automotive parts die castings are tested. A rear LED fiber optic light guide system with up to 100,000 lux illumination provides a brighter source of light for inspection. 2.4mm/2.8mm/3.9mm/6mm diameter pipeline, length 1-8m. Automatic white balance and image noise reduction make the picture clearer and sharper, giving users a more detailed detail image.

At present, Yateks videoscope is mainly used in automobiles, aero engines, pipelines, mechanical parts, etc. It can realize non-destructive testing without disassembly or destruction of assembly and equipment stop operation, and can also be used for ventilation ducts, air conditioning ducts, water pipes, industrial pipes. Video inspection of internal welds, corrosion, clogging, differences, foreign objects, etc.