In the world of industrial maintenance, the greatest challenges are often hidden from view. Cracks deep within a turbine, corrosion in a complex pipeline, wear and tear in a hard-to-reach gearbox—these issues can lead to catastrophic downtime, costly repairs, and significant safety hazards if left undetected.

For decades, inspecting these areas meant guesswork, costly disassembly, or both. Not anymore.

Welcome to the next generation of industrial inspection. Welcome to the power and precision of modern Industrial Borescopes.

What is an Industrial Borescope?

An industrial borescope is a sophisticated optical device consisting of a flexible or rigid tube with a high-resolution camera at one end and a display screen at the other. It allows inspectors to visually explore the interior of machinery, engines, pipes, and other confined spaces without the need for destructive disassembly.

Think of it as a powerful set of eyes that can navigate the tightest, most complex spaces in your facility.

Why Your Operation Needs a High-Quality Borescope

1. Drastically Reduce Downtime

Time is money. Traditional inspection methods can take hours or even days just to access a component. A borescope inspection can often be completed in minutes, providing immediate visual evidence to make informed decisions. Get your equipment back online faster and keep your production schedules on track.

2. Save Significant Costs

Avoid unnecessary teardowns. By confirming the condition of a component internally, you can prevent the labor costs associated with disassembling perfectly healthy machinery. More importantly, early detection of minor issues allows you to address them before they escalate into major, budget-breaking failures.

3. Enhance Safety

Inspect hazardous or difficult-to-access areas—such as live electrical systems, toxic environments, or high-temperature chambers—from a safe distance. Protect your personnel by minimizing their exposure to potential risks.

4. Improve Documentation and Reporting

Our advanced borescopes come equipped with features like high-definition photo capture, video recording, and WiFi streaming. Document your findings with crystal-clear evidence to create maintenance reports, share with team members for collaborative analysis, or provide proof to clients and stakeholders.

5. Versatility Across Industries

No matter your sector, there’s an application for a borescope:

Aviation & Aerospace: Inspect turbine blades, combustion chambers, and airframe structures.

Automotive: Examine internal engines, cylinders, and transmissions without rebuilds.

Power Generation: Check turbines, boilers, and heat exchangers for corrosion and damage.

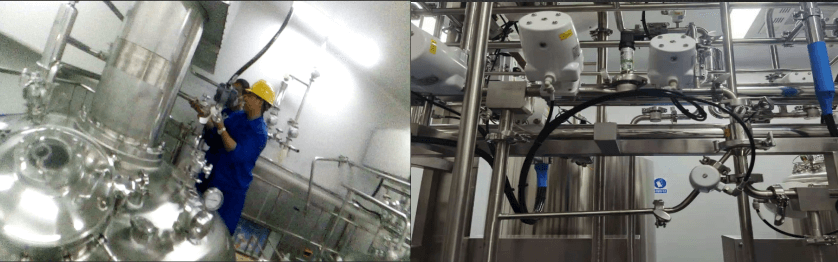

Manufacturing: Ensure the integrity of welds, castings, and complex machinery.

Oil & Gas: Maintain pipelines, valves, and wellheads with confident internal assessment.

Key Features to Look For in Your Next Borescope

Not all borescopes are created equal. Our cutting-edge models are engineered for excellence in the toughest environments:

Superior Articulation: A articulating tip allows you to navigate twists and turns with precision, ensuring you never miss a critical angle.

Crystal-Clear Imaging: High-resolution CMOS sensors and bright LED lighting provide a bright, detailed view, even in complete darkness.

Rugged & Durable Design: Built to withstand industrial environments with IP67 waterproof ratings and abrasion-resistant insertion probes.

User-Friendly Interface: Intuitive controls, portable monitors, and smartphone connectivity make inspections efficient and straightforward.

Stop Guessing. Start Inspecting.

Don’t let hidden problems dictate your bottom line. Empower your maintenance team with the visual intelligence they need to predict, prevent, and solve problems proactively.

Ready to see what you’ve been missing?

Yateks borescope offers a full range of industrial borescopes to meet your specific needs and budget. Our experts are ready to help you find the perfect inspection solution.

Contact us today for a consultation or to request a live demo!

Visit our website: www.yateks.com

Email: [email protected]

WhatsApp:+86 15217763651