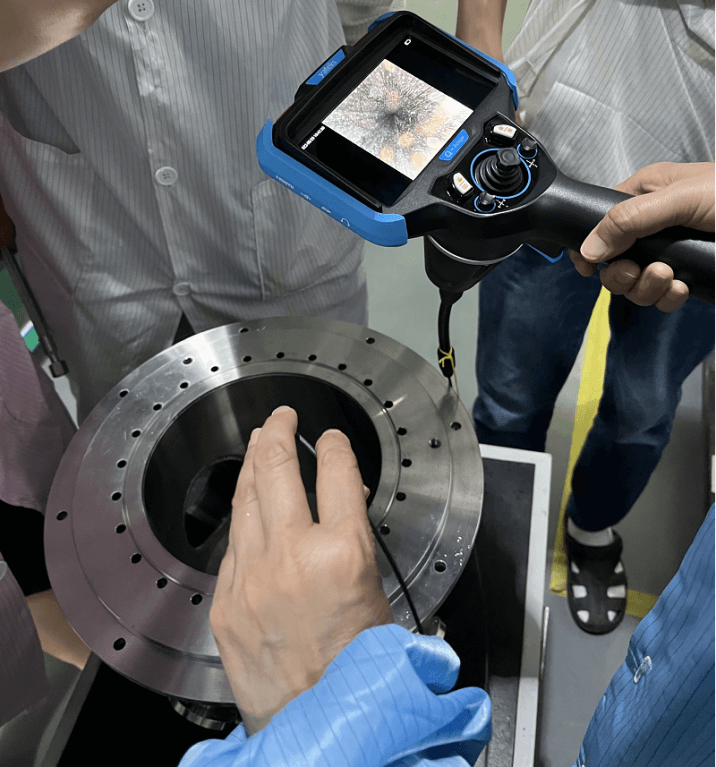

An articulating video borescope is a specialized inspection tool used for visual inspection of heat exchangers and tubing. It consists of a flexible insertion tube with a camera and lighting system at its tip, and a handheld display or monitor for viewing the captured video footage in real-time.

Here are some key features and benefits of using an articulating video borescope for heat exchangers and tubing inspection:

Articulation

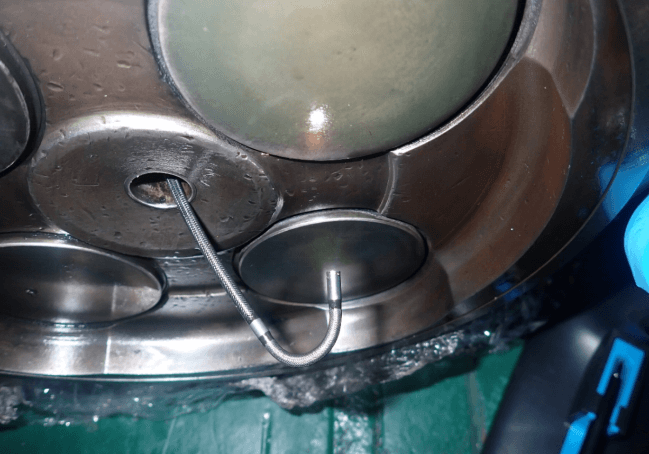

The insertion tube of the video borescope can be bent or articulated, allowing for easy navigation through complex tubing and hard-to-reach areas. This flexibility enables thorough inspection of the internal surfaces of the heat exchanger and tubing.

High-resolution imaging

The video borescope captures high-quality images and videos of the internal surfaces, ensuring clear visibility of any defects, corrosion, fouling, or blockages within the heat exchanger or tubing.

Lighting system

The borescope is equipped with built-in LED lights to illuminate the inspection area, making it easier to detect any abnormalities or damages within the heat exchanger or tubing.

Real-time viewing

The captured video footage is displayed in real-time on the handheld monitor or display, allowing inspectors to immediately identify any issues and take necessary actions.

Documentation and reporting

Video and image documentation can be captured during the inspection, enabling detailed analysis and generating comprehensive inspection reports for future reference or compliance purposes.

Remote inspection capability

Some articulating video borescopes have wireless or remote viewing capabilities, allowing inspectors to share the live video feed with others for collaborative troubleshooting or remote guidance.

Cost-effective and time-saving

Using a video borescope for heat exchanger and tubing inspection eliminates the need for costly and time-consuming methods such as disassembling, cutting, or removing the equipment. It speeds up the inspection process and reduces equipment downtime.

By leveraging an articulating video borescope for heat exchangers and tubing inspection, you can effectively identify and address issues such as corrosion, fouling, blockages, or leaks, ensuring optimal performance, energy efficiency, and prolonged equipment lifespan.