The customer is mainly engaged in mobile phone, battery, computer accessories and other related supporting parts, and the customer wants to use the endoscope to detect the aluminum alloy machined parts produced. It is used for pressing the back cover of the mobile phone. When the customer produces the back cover of the mobile phone, they will use the abrasive tool, which is called the aluminum alloy machined part internally. The staggered holes on the aluminum alloy machined parts are of different sizes, and it is necessary to use an endoscope to see the burrs at the internal holes.

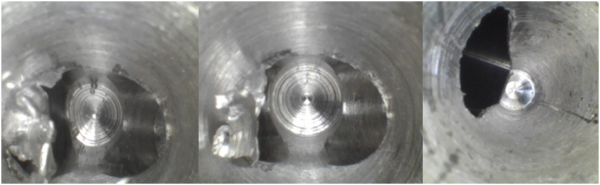

The main consideration of customers is not to reduce the detection effect and product price. Take a look at the measured effect of Yateks endoscope equipment. After the preliminary communication and docking between the two parties, the Yateks endoscope sales engineer arrived at the customer’s demonstration site at the agreed time. The industrial endoscope models demonstrated this time are mainly M series industrial endoscopes, 2.2mm direct view, 2.8mm direct view, 3.0 side view and other types of endoscopes. In order to test the trial performance of the equipment in the water environment, in the afternoon, the customer deliberately used the newly purchased high-pressure water gun to wash the aluminum machined parts, and then used the Yateks industrial endoscope to verify and test again. The workshop usually measures 500-600 materials a day. More than 10 people in a shift have to use equipment to check all the year round, and the oil pipe connection is used for verification after testing. During the on-site measurement, Yateks diameter 2.8mm was used to measure 4mm small holes. Because the endoscope module was too close to the inner wall, the detection effect was average. After the sales engineer switched to the 2.2mm diameter endoscope equipment for inspection, the person in charge of the customer site read it. Immediately after the demonstration, he said that the Yateks endoscope equipment had a very good effect and was very clear, and recorded video and images of the detection effect with a mobile phone on the spot.

After continuous communication between the two parties, the customer feedback: In its BSC system, the customer will use this small-aperture endoscope as a daily tool instead of industrial equipment. As a user of the tool, the customer will consider more The most important thing is the cost of use, durability and low consumption, and the endoscope product demonstrated this time just meets its requirements, and I immediately decided to purchase it.

Yateks has a complete range of industrial endoscope products, which are used in multiple industry inspections. Products are sold all over the world, and there are distributors in many countries who can provide you with localized services. If there is a need, please contact us.