Deep within the heart of a locomotive, in the precise gaps where gears mesh, or inside oil-covered pipelines—hidden faults often lurk in dark corners invisible to the naked eye. Every unexpected breakdown and every safety concern tests the wisdom and efficiency of the maintenance team.

How can these locomotives undergo precise and efficient “health check-ups”? Yateks Industrial Endoscopes have become an indispensable tool in the hands of locomotive maintenance engineers!

What Challenges Exist in Locomotive Maintenance?

-

Internal wear of diesel engine cylinders, piston ring conditions, carbon buildup in combustion chambers

-

Gear engagement inside gearboxes, bearing conditions

-

Blockages or corrosion in narrow oil and air pipelines

Inspecting these critical components traditionally requires time-consuming disassembly, which may even introduce new risks.

-

Complex structures like bogie interiors, hidden cavities in the locomotive body, and tiny pipelines make manual inspection difficult.

-

Harsh environments filled with oil and moisture degrade visibility, affecting defect detection accuracy.

How Can Yateks Industrial Endoscopes Solve These Problems?

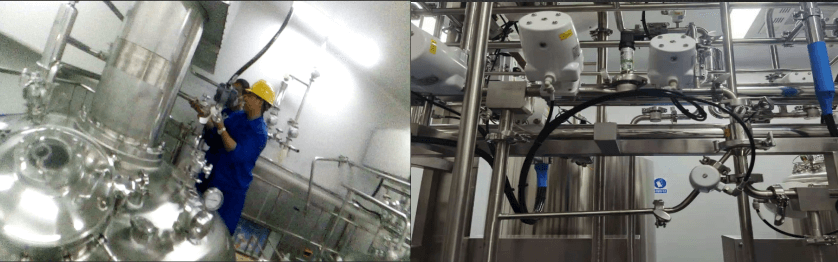

With years of expertise in industrial nondestructive testing, Yateks’ series of industrial endoscopes are designed to address the core challenges of locomotive maintenance:

-

Ultra-Slim & Flexible Insertion Tube (as small as 0.85mm in diameter)

-

Navigates through tight gaps, curved pipelines, and hard-to-reach areas like cylinder interiors, gearboxes, cooling channels, and brake system pipelines—minimizing disassembly, reducing downtime and labor costs.

-

-

2-megapixel HD camera with high-quality fiber optic lighting system

-

Delivers bright, clear, and color-accurate imaging even in oily or humid conditions, revealing micro-cracks, wear, corrosion, foreign objects, and assembly defects with precision.

-

-

360° Omnidirectional Steering for Full Coverage Inspection

-

The probe offers high-precision articulation, allowing engineers to inspect blind spots effortlessly and detect potential faults.

-

-

Rugged Design for Harsh Environments

-

Built with IP67-rated waterproof, oil-proof, dust-proof, and corrosion-resistant properties, suitable for workshops and field operations.

-

-

Smart Documentation & Management

-

Records HD videos and photos, generates detailed inspection reports, and enables archiving, expert consultation, and data-driven maintenance decisions.

-

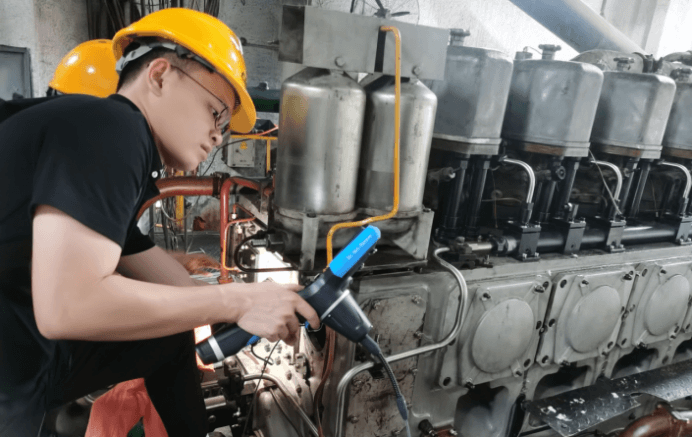

Real-World Case Study

A leading locomotive manufacturer specializing in electric, diesel, and hybrid locomotives adopted the Yateks Q-Series endoscope (2-megapixel HD camera, 6mm lens, 2m insertion tube, 360° rotation) to inspect:

- Gear engagement, tooth surface damage, and bearing conditions under heavy loads.

Results:

- 300% improvement in gear wear detection efficiency

- 92% accuracy in bearing fault diagnosis

- Over 1 million USD saved annually in preventive maintenance costs

Yateks Industrial Endoscopes, with their high-definition imaging, flexibility, and durability, have become a critical tool in modern locomotive maintenance systems. They provide engineers with “X-ray vision” to uncover hidden defects, ensuring safe, efficient, and long-term operation of locomotives.