Heat exchanger refers to the process of transferring heat from hot fluid to cold fluid, so that different temperature differences are generated inside and outside the pipe to achieve temperature regulation.

Heat exchangers usually use water as a medium to generate high temperature and high pressure steam by heating. Heat exchangers can be mainly divided into two types: multi-tube heat exchangers and plate heat exchangers. Multi-tube heat exchangers are widely used in factories and are commonly used piping equipment in factories. Compared with the multi-tube heat exchanger, the size of the plate heat exchanger is easier to reduce, and the medium can pass through the guide plate composed of grooved plates.

What problems can occur with heat exchangers?

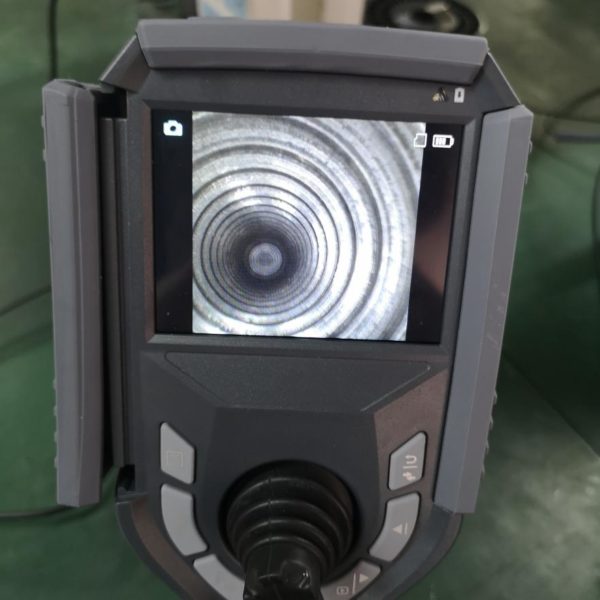

During the long-term use of the heat exchanger, due to frequent contact with water vapor and other factors, abnormal conditions such as scale, corrosion, blockage, cracks, and sediments are likely to occur in the heat exchanger, which seriously affects its use efficiency. Usually the heat exchanger with severe corrosion can only be scrapped.

Why do you need an industrial endoscope to inspect heat exchanger?

Don’t wait until a serious problem occurs to check the condition of the heat exchanger. Regular visual inspections are a critical part of ensuring manufacturing or power generation operations. Preventive maintenance, including remote visual inspections, is more economical than waiting for a breakdown to be repaired.

What are the advantages of Yateks M series Articulating Borescope?

Therefore, it is particularly important to regularly detect whether there is any abnormality in the internal structure of the heat exchanger. Yateks is a professional industrial endoscope brand. The M series high-definition industrial endoscopes can efficiently deal with the daily inspection and maintenance tasks of heat exchangers and other equipment. The M series high-definition industrial endoscope has the advantages of 360° all-round steering function of the probe, mega high-definition pixels, waterproof, dustproof and high temperature resistance, long battery life and other advantages. At the same time, the endoscope has the recording function, you can test the equipment very well operating status. It can be used for non-destructive testing and maintenance in aerospace, power plants, urban rail transit and other fields.