Diesel engines are internal combustion engines. It works by using high pressure and ignition to convert fuel into energy. Therefore, there will be high temperature and pollutants inside for a long time, and it is particularly prone to internal corrosion and operational problems. Therefore, it is necessary to regularly check all parts of the diesel engine, such as: valves, pistons, cylinders, etc., to ensure the normal operation of the equipment.

With the continuous improvement of industrial technology, the technology of diesel engines is also constantly updated, and the proportion of use is naturally gradually increasing. The performance of many domestic diesel engine companies has shown an upward trend. Industrial borescopes have also begun to play a greater role in the field of diesel engine inspection.

Diesel engines use air and fuel to work together to convert fuel into energy. Compared with other types of engines, diesel requires a higher air pressure value, which will be more tolerant to the surrounding solid materials, so the key to diesel engines Site safety is crucial in long-term use;

Can the industrial borescope check the problems of the engine?

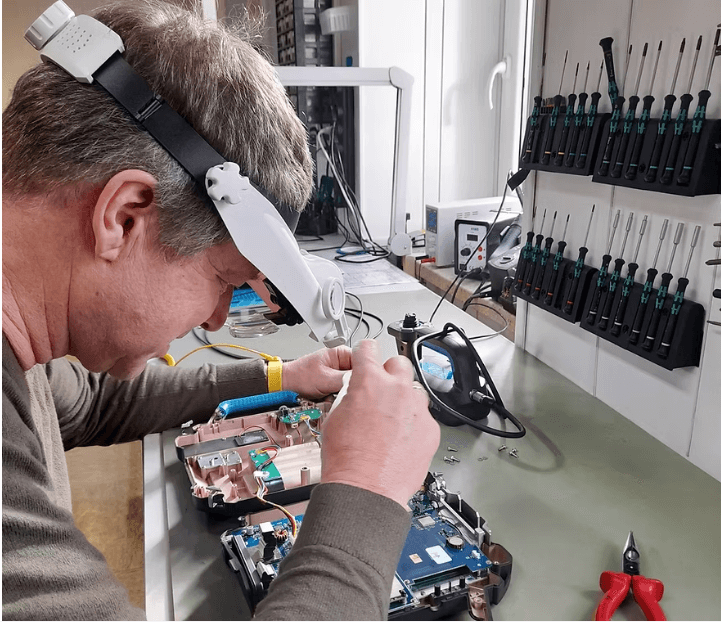

During the manufacturing process of these important parts, industrial borescopes must be used for non-destructive testing to ensure quality and safety. Inspectors often need to check whether there are rust, cracks, burrs and other defects in the detailed parts, and check unqualified products in time. Rework maintenance; and in the future use process, regularly conduct internal quality inspections of equipment, so that problems can be repaired in time;

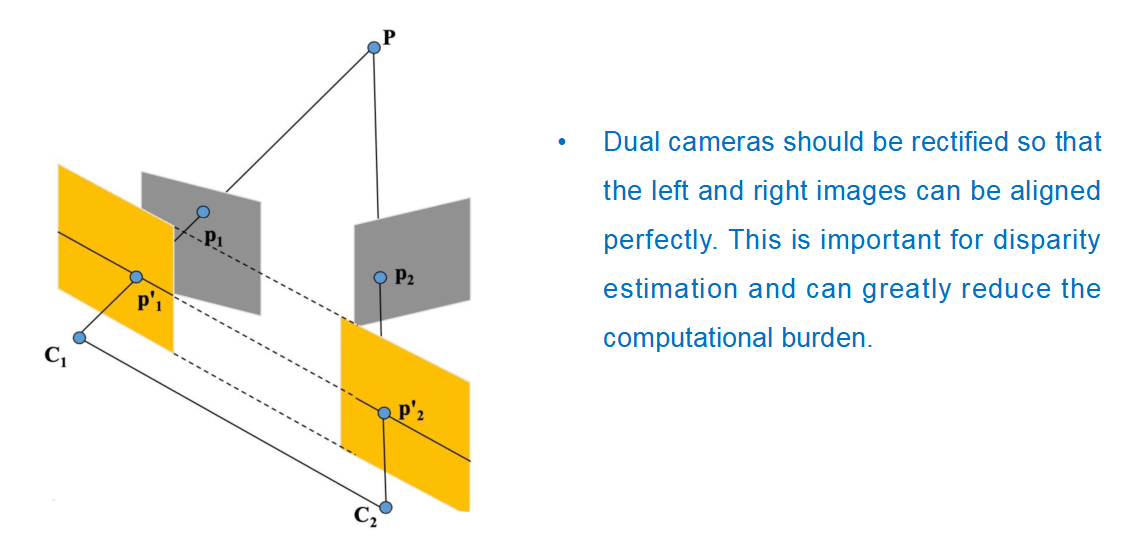

In the early days, the only way to check the internal quality of a diesel engine was to disassemble the equipment and observe the detailed parts bit by bit with the naked eye. Now, with the development of non-destructive technology, the industrial borescope has become the primary equipment for engine inspection. It does not need to be disassembled. It only needs to extend the front-end probe into the equipment through the insertion hole. The million-level high-definition pixels and LED adjustment lights can be seen. Clear any blind spots, help inspectors extend their vision, and get twice the result with half the effort;

Yateks industrial borescope can customize various equipment models for customers, and can independently choose the length, diameter, pixel, and depth of field of the pipeline according to their actual inspection needs, and match the actual inspection environment. If you also have related inspection needs , feel free to contact us.