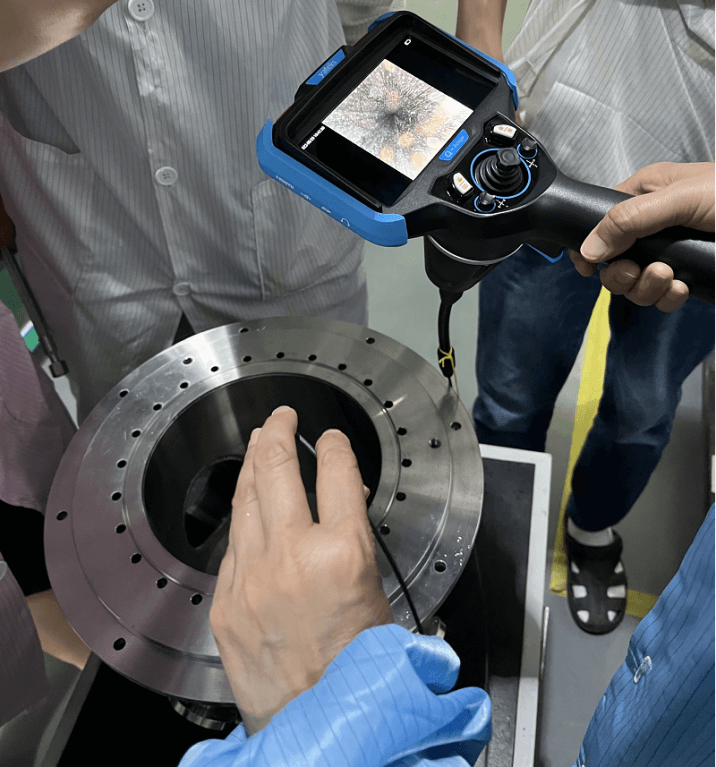

In order to better maintain traffic equipment and ensure rail traffic safety, industrial borescope equipment is often used in rail traffic. Use borescope to inspect parts of the train body that cannot be directly observed. This visual inspection method requires neither disassembly of parts nor damage to the body. He needs to go directly through the front-end probe of the industrial endoscope to observe the internal conditions of the car body components, including the inner side of the running part (bogie), the inner spring of the bolster, the train coupler, etc., and observe foreign objects such as dropped screws, etc. Cracks, damages, etc., so as to facilitate the staff to repair and take treatment measures in a timely manner.

The use of industrial borescope detection, on the one hand, greatly reduces the workload of the inspection personnel and improves the work efficiency. On the one hand, it is economical and practical, and has a wide range of uses; on the other hand, it is relatively simple to use and does not require special training, which effectively ensures the safe and stable operation of the train and brings a comfortable ride experience to passengers. As a commonly used non-destructive testing tool, it has a wide range of applications in the maintenance and inspection process of various vehicles such as subways, high-speed rails, automobiles, ships, and airplanes.

Industrial borescope are commonly used in the field of non-destructive testing to detect the following aspects:

-

Internal cavity inspection.

Inspect parts or materials for internal surface cracks, peeling, pulls, scratches, pits, bumps, spots, corrosion and other defects.

-

Assembly inspection.

-

When the assembly or a certain process is completed, check whether the assembly position of each parts and components meets the requirements of the drawings or technical conditions, and whether there are assembly defects to ensure the assembly quality.

-

Weld surface defect inspection.

Check for various defects such as cracks on the inner surface of the weld, lack of penetration and weld leakage.

-

Excess inspection.

Check the inner cavity of the product for residual internal chips, foreign objects and other excesses.

-

Operation status check:

Observe the inside of the equipment, check the operation status, and detect whether there is any abnormality.

Yateks’ industrial borescopes have a wide range of applications and a complete range of products. Yateks’ industrial borescope, the product has good durability and long service life. We have dealers in many countries around the world who can provide you with a door-to-door demonstration.