Metal pipes form the vital arteries of modern industry—transporting everything from critical fuels and chemicals to life-saving medical gases. In the automotive, aerospace, energy, and medical device sectors, a single undetected flaw can lead to catastrophic failure, costly downtime, or compromised safety. Ensuring the integrity of these pipelines isn’t just important; it’s non-negotiable.

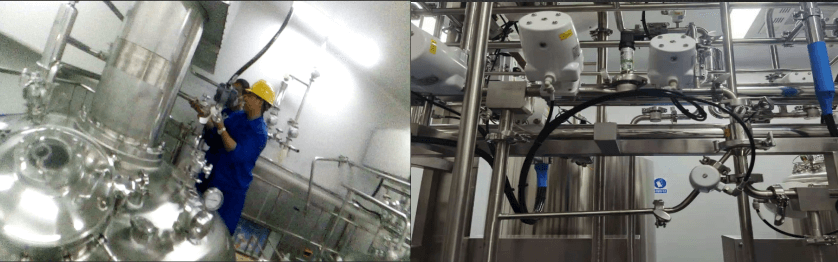

At Yateks, we specialize in Remote Visual Inspection (RVI) technologies that allow you to see the unseen. As a manufacturer of advanced industrial endoscopes and camera systems, we provide the eyes inside your most critical components, delivering clarity, confidence, and control over your quality assurance processes.

The High Cost of Hidden Flaws

Corrosion, pitting, weld defects, blockages, and cracks—these internal threats can remain invisible during external inspections. Traditional inspection methods often require destructive testing, costly disassembly, or lengthy system shutdowns. In today’s competitive and efficiency-driven landscape, such approaches are no longer sustainable.

See Inside, Stay Ahead: The Yateks Solution

Our industrial video endoscopes are engineered for precision, durability, and ease of use in challenging environments. They transform metal pipe inspection from a disruptive, uncertain task into a fast, reliable, and data-driven procedure.

Key Features of Yateks Inspection Systems:

-

High-Definition Visualization: Ultra-sensitive cameras and adjustable LEDs illuminate even the darkest pipes, revealing surface details down to the finest crack or smallest spot of corrosion.

-

Robust & Articulated Probes: Our durable, flexible, and often articulating scopes navigate complex pipe networks, bends, and welds, delivering a complete internal panorama.

-

Portable & Efficient: Lightweight, portable units enable inspectors to perform immediate on-site inspections without disassembly, minimizing operational interruption.

-

Documentation & Reporting: Integrated software allows for image capture, video recording, and annotation. Generate detailed reports with evidentiary documentation for compliance, maintenance records, and failure analysis.

Tangible Benefits for Your Operation:

-

Prevent Failures: Proactively identify and address issues before they escalate into leaks or ruptures.

-

Reduce Downtime: Inspect pipes in minutes, not days. Avoid unnecessary disassembly and extend service intervals.

-

Cut Costs: Eliminate the high expenses associated with reactive repairs, production stoppages, and collateral damage.

-

Ensure Compliance: Meet stringent industry standards (like ASME, API, or ISO) with verifiable, documented proof of internal condition.

-

Enhance Safety: Protect personnel and the environment by preventing unexpected releases of hazardous materials.

Application Scenarios:

-

Pre-Inspection of New Welds & Installations

-

Routine Preventive Maintenance Schedules

-

Root Cause Analysis of Suspected Failures

-

Post-Repair or Post-Cleaning Verification

-

Inspection of Hard-to-Access Lines in Congested Plant Areas

At Yateks, we believe that true quality is internal. By bringing the hidden world of your pipework’s interior into sharp focus, we empower engineers and inspectors to make informed decisions that ensure system reliability, safety, and longevity.

Don’t let critical flaws remain in the dark.

Explore the future of non-destructive testing. Contact Yateks today to discover how our tailored industrial endoscope solutions can bring clarity and confidence to your metal pipe inspection program.