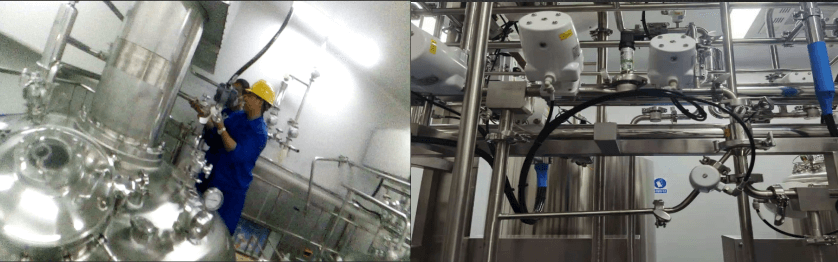

When a leading chemical plant faced unexpected efficiency drops in their shell & tube cooler systems, traditional inspection methods would have required 3 days of downtime and complete bundle extraction. Instead, they chose the Yateks Q Series Industrial Borescope—and completed the inspection in just 4 hours. This is one of many real-world applications where our 4.0mm diameter, 1-meter length borescope has transformed maintenance operations.

Real Case Study: Quick Problem Identification, Zero Disassembly

Client: Chemical Processing Facility

Challenge: Suspected tube blockage in a critical shell & tube cooler affecting heat transfer efficiency

Solution: Yateks Q-Series Borescope with 4.0mm diameter probe

Result:

Within 2 hours, technicians identified 12 partially blocked tubes and 3 with early-stage corrosion

No disassembly required—inspection performed during scheduled maintenance window

Repair plan implemented immediately, preventing potential unplanned shutdown

Estimated cost savings: $18,000 in avoided downtime and labor

Why the Yateks Q-Series Is Redefining Industrial Inspections

✅ 4.0mm Slim Design, Unmatched Access

The ultra-slim profile allows entry into even the most restrictive tube configurations. Unlike bulkier scopes, our 4.0mm probe navigates standard cooler tubes with ease, providing complete visual coverage without compromise.

✅ 1-Meter Reach, Complete Coverage

With a full meter of flexible yet durable probe length, technicians can thoroughly inspect deeper sections of tube bundles, U-bends, and shell-side cavities—reaching areas previously accessible only through complete disassembly.

✅ Real-World Tested Durability

Used in refineries, chemical plants, and power facilities worldwide, the Q-Series withstands high temperatures, moisture, and chemical exposure while delivering consistent performance inspection after inspection.

✅ Documentation That Drives Decisions

High-resolution imaging and video capture provide clear evidence for maintenance planning, compliance reporting, and repair validation—turning visual data into actionable insights.

How Professionals Are Using the Q-Series Today

Preventive Maintenance Teams conduct quarterly tube inspections to detect fouling trends and plan cleaning schedules

Integrity Engineers verify weld quality and joint integrity during fabrication and installation

Plant Managers use inspection reports to optimize cooler performance and extend equipment lifespan

Safety Officers identify potential failure points before they become emergencies

Technical Specifications That Matter

Probe Diameter: 4.0mm (fits standard tube configurations)

Working Length: 1 meter (complete access to most cooler designs)

Image Quality: High-definition with adjustable LED illumination

Bending Radius: Flexible 180° articulation for navigating complex paths

Environmental Rating: IP67 waterproof, chemical-resistant construction

Software Included: Report generation and image management tools

Join Our Growing List of Satisfied Clients

“With the Yateks Q Series, we reduced our cooler inspection time by 75% and eliminated the need for mechanical disassembly. The 4.0mm probe gets where we need to see, and the 1-meter length covers our entire tube bundle.”

— Maintenance Supervisor, Power Generation Plant

Experience the Difference Yourself

Stop guessing what’s inside your equipment. See it clearly with the Yateks Q-Series.

Schedule Your Live Demo Today

Email: [email protected]

Visit: www.yateks.com