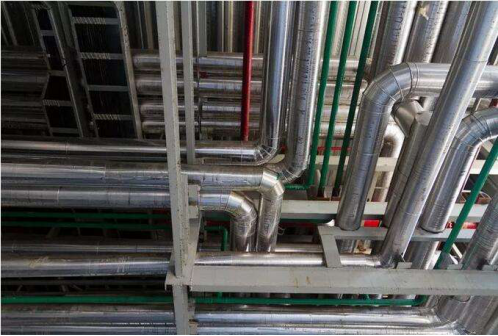

As we all know, foreign objects in food and poor hygiene have always been the most strongly reported problems by consumers, and they also account for the largest proportion of many quality complaints. Therefore, food production enterprises should minimize the possibility of foreign matter mixing. In all kinds of food production, pipeline welding operations are very common. Dead corners, there is a greater quality risk. Today we mainly talk about the welding method of industrial boresope to verify the pipeline of food factory.

The connection of clean pipelines needs to be welded. In the process of prefabricated welds and on-site welds, it is necessary to ensure that the appearance of the welds conforms to relevant standards, to ensure that the welds are uniform, well formed, uniform in width, smooth, defect-free, and free of oxidation. Discoloration, no pinholes, no cracks, eliminate all kinds of defects that may occur, such as depressions, unevenness, incomplete penetration and so on on the inner surface of welding. Using an industrial borescope for inspection can clearly see various welding conditions on the inner surface of the pipeline, and can take pictures and save it. It is a non-destructive testing instrument commonly used in the food pipeline industry.

In response to different user needs of food and pharmaceutical production pipelines, Yateks industrial borescopes have launched a series of industrial endoscopes, which can provide users with high-quality pipeline weld inspection services. Yateks industrial borescope has replaceable technology with different probe functions, diameters and lengths to meet the requirements of different inspection pipe diameters. The lens can be rotated 360 degrees to provide users with high-quality welding seam inspection images.

Yatek industrial borescopes can inspect pipes of different lengths and diameters, and can accurately and quickly detect conditions such as pipe welds, inner wall attachments, and pipe inner wall wear conditions, so that manufacturers can use one product to meet different conditions. corresponding solution.