When inspecting and accessing tight spaces, having the right video borescope is a must. But Yateks have so many different types and sizes of video borescopes available, how do you know which one is best for your application? This guide will help you figure out which features are important when choosing a video borescope, so you can make an informed decision about what’s best for your needs.

Yateks Video Borescope Choices

When choosing a video borescope for your application, there are multiple considerations that must be made to select the right tool for the job:

- Inner Diameter (part opening and core passage being inspected)

- Outer Diameter(video borescope)

- Field of view

- Direction of view

- Articulation

- Illumination

1. INNER DIAMETER OF PART

Simply put, the inner diameter, or ID, refers to the width of the part’s bore or passage being inspected, usually measured in units of inches or millimeters. Knowing your part/application ID dimensions is critical. This is the first consideration in choosing a video borescope.

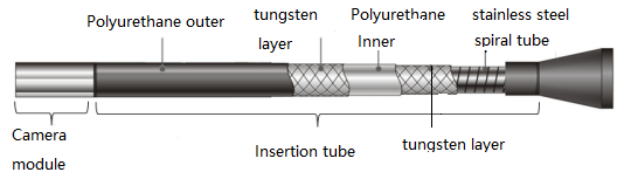

2.OUTER DIAMETER OF SCOPE

The outer diameter, or OD, of the video borescope is the width of the scope tip. Usually measured in millimeters, this criterion is also critical in choosing the proper scope for your application. Certain ODs of scopes work well with certain part/application ID’s.

3.FIELD OF VIEW

Field of view (FOV) is the visible area a video borescope can see at once.

4.DIRECTION OF VIEW

Video Borescope Direction of View DOV

Direction of view (DOV) refers to orientation of the camera sensor on the distal tip of the video scope. Direct view looks forward (or 0°) from the scope tip, side view looks to the side (or 90°), and dual view can look in either direction. 0° DOV scopes are useful in locating defects inside parts as you maneuver into a part, and 90° DOV scopes are useful for closer side-wall inspection and documentation. Dual view (both 0° and 90°) provides both options for more thorough inspections.

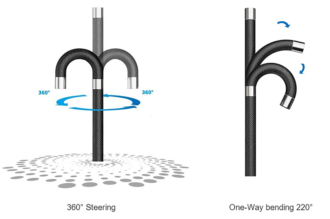

5. ARTICULATION

Articulation refers to whether a video borescope can move the distal tip of the scope from a simple control mechanism. 2-way articulation means a scope can sweep back and forth on a single plane. 4-way articulation means a scope can sweep back and forth on 2 separate planes allowing for more inspection coverage without scope rotation. The below illustrates the difference between 2 and 4-way articulation.

6. Illumination

For front lighting, the light source is usually mounted directly on the lens.

For rear lighting, the light source is usually installed in the main body, and the strong light produced by the bulb is transmitted to the end of the endoscope probe by a special optical fiber, and is emitted from a special window at the end.

Which lighting technology is more advantages?

The front lighting installs the light source at the front of the probe, which requires in-depth internal inspection. Long-term back and forth friction will cause LED wear and reduce the service life of the light source. And due to the limitation of the probe diameter, the narrow space limits the power of the light source. However, the cost of the front LED light is low, the installation process is relatively simple, and the cost performance is high

Rear lighting, the light source is in the host, there is no space limitation, a high-power light source can be used, and the lighting brightness is sufficient to ensure image clarity. At the same time, fiber optic lighting has a wider color gamut, higher color saturation, and better color expression, but this kind of fiber-optic rear lighting is more expensive.