Die casting is a metal casting process characterized by the use of a mold cavity to apply high pressure to the molten metal. Molds are usually machined from higher strength alloys, some of which are similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys, as well as alloys thereof. Depending on the type of die casting, a cold chamber die casting machine or a hot chamber die casting machine is required.

Compared to other casting techniques, the die-cast surface is flatter and has a higher dimensional consistency. However, non-standard operations and parameters can also produce a wide variety of defects. The main defects are as follows:

1. Pulling die: The strip surface is scratched along the surface of the casting in the mold opening direction, and has a certain depth. In severe cases, it is a surface flaw. The other is that the molten metal is bonded to the mold, adhered and pulled, so that the surface of the casting is rich or lacking in material;

2. Bubbles: The surface of the casting has ridges of different sizes, or there are voids formed under the skin;

3. Cracks: There are linear or irregular irregular lines on the surface of castings, which have a tendency to develop under the action of external forces. Cold cracking—The metal at the crack is not oxidized. Thermal cracking—the metal at the crack is oxidized;

4. Deformation: The geometry of the die casting does not match the drawing. Overall deformation or local deformation;

5. Traces and patterns: Appearance inspection, there are stripes on the surface of the casting that are consistent with the flow direction of the molten metal, and there are obvious lines that are not the same as the color of the metal matrix, and there is no development trend;

6. Layering: Appearance inspection or damage inspection has obvious metal levels in the casting. ……

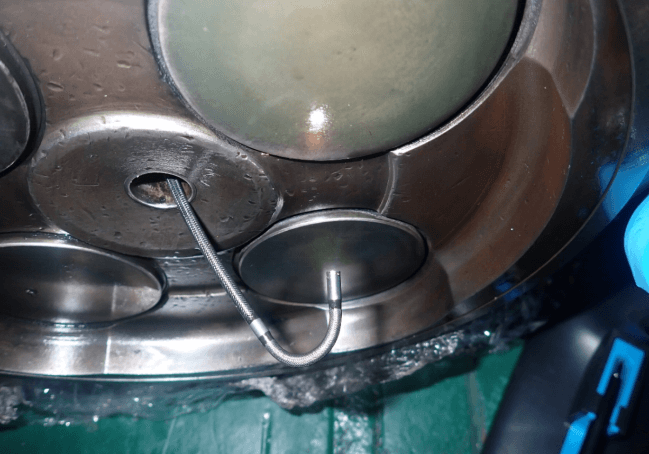

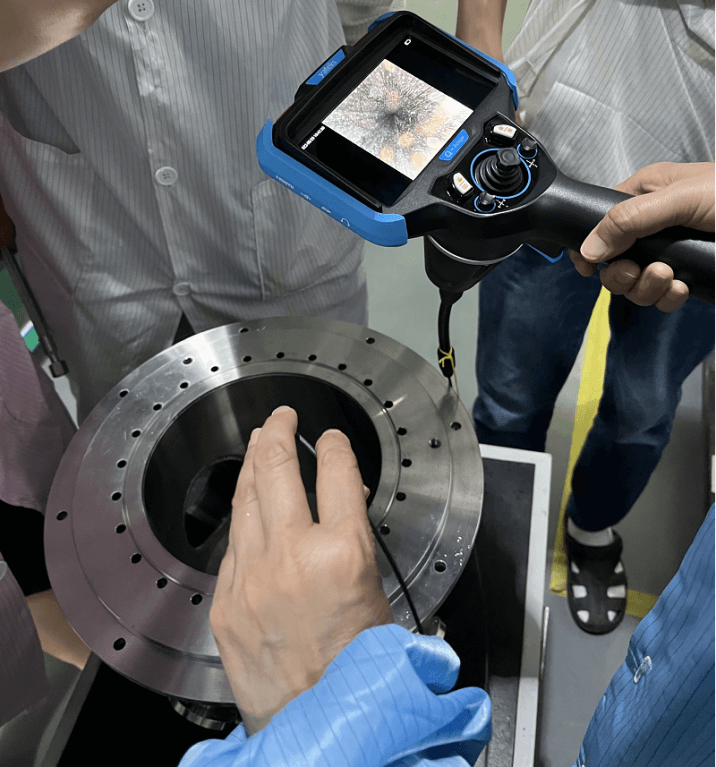

Yateks videoscope adopts megapixel COMS high-definition camera with 8-inch high-quality industrial-grade touch screen, high-definition image restoration effect, the whole machine integrated portable design is lighter, and the detection probe 360° omnidirectional guidance is used for Different automotive parts die castings are tested. A rear LED fiber optic light guide system with up to 100,000 lux illumination provides a brighter source of light for inspection. 2.4mm/2.8mm/3.9mm/6mm diameter pipeline, length 1-8m.

The user can enter the casting borescope high-definition lens into the interior of the casting, and directly observe the cracks, bubbles, deformation and other defects inside the display through the display screen, and can save by taking photos and videos.