Cars are an indispensable means of transportation. In order for people to ride in a safer and more comfortable car, endoscopy has become an indispensable detection method in the automotive and parts industry. The use of industrial endoscopes as a visual inspection device is very efficient. At present, there are many inspection locations commonly used, including carbon deposits near the valve position of the engine, burrs generated by various machining intersecting holes, defects such as trachoma burrs in castings, and check the quality of welding positions and the quality of filling inside the car body And so on, these have become the most important inspection locations in automobile manufacturing.

Below we select a few specific applications of the high-definition portable Yateks Industrial Endoscope for a brief introduction:

- Observation of carbon deposit on automobile engine valve

During driving, because of incomplete fuel combustion, carbon deposits will be generated in the cylinders, which will affect the combustion efficiency of the car. Observation through a high-definition endoscope can see the severity of carbon deposits. Observation of the valve is not only A high-definition endoscope is required, and there are relatively high requirements for color recognition. Yateks Industrial Endoscope has obvious advantages in the accuracy and smoothness of color display, which can avoid the misjudgment of engineers to the greatest extent. At the same time, a high endoscope guiding ability is required to facilitate the observation of different positions in the cylinder. At present, it is widely used in cylinder inspection and aftermarket maintenance of various brands of automobiles.

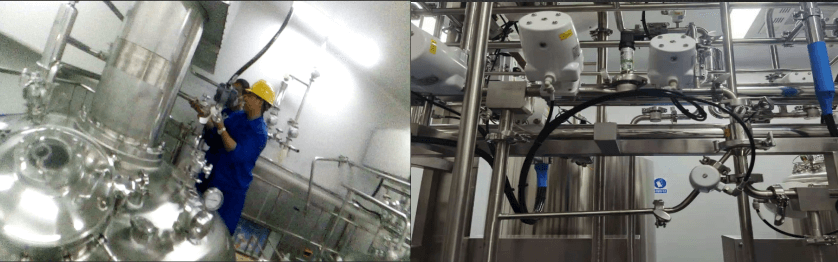

- Various inspections of casting parts

There are many cast parts in automobiles, and some of the parts have complex structures, and defects such as shrinkage, trachoma, and burrs will occur during casting. The inspection of such parts can also make the endoscope show its skills. The following are the inspections of turbocharger castings performed by turbocharger manufacturers using Olympus endoscopes:

The internal structure of the turbocharger is difficult to observe completely with an endoscope, but relying on excellent guiding ability and a relatively large field of view, engineers still get a very clear and complete real picture. At the same time, during long-term inspection, the abrasion of the endoscope skin is inevitable, but the endoscope of Yateks has four layers of protection, which can protect the body of the endoscope to the maximum extent, greatly extend the service life and reduce the use of manufacturers. The cost of endoscopy. The inspection endoscope for castings in the remaining parts also has advantages that other inspection equipment does not have, such as the ability to determine the size of the defect.

- Inspection of weld seam and body

Industrial endoscopes are also widely used in other parts of the car, such as the inspection of weld quality and the inspection of car body fillers. Both of these two types face the limitations of traditional endoscopic observation methods, that is, the reflection of the weld seam and possible insufficient brightness during vehicle body inspection cannot be avoided, and high-definition images cannot be obtained. Because the welding place is the hardest hit area of reflection, if you want to see clearly, the equipment itself needs to have good anti-reflective ability and can automatically adjust the brightness.

Industrial endoscopes can also perform inspections of oil and water circuits, exhaust manifolds, catalyst devices, cylinder blocks, cylinder heads, and camshaft machining. It can be said to be the most important method for internal inspections of automobiles at present. Consumers’ requirements for the quality of automobiles continue to increase. At the same time, new energy vehicles are also developing rapidly. There are more new transmissions and power devices that need to be inspected. Automobile manufacturers and spare parts companies will use endoscopes more and more frequently. , As the car ownership is increasing year by year, the demand in the automotive aftermarket will continue to increase, and the performance requirements for industrial endoscopes will also be higher and higher. Yateks Industrial Endoscope is currently in a leading position in the automotive and parts manufacturing applications at home and abroad. It has been deeply involved in the automotive industry for decades, and its equipment is almost everywhere in all automotive brand manufacturers.