Industrial borescope is a non-destructive testing instrument that can go deep into areas that cannot be directly seen by the human eye. Its front-end pipeline can be bent to enter narrow, high-temperature, toxic and other spaces for visual inspection, which can reduce the workload of inspection personnel. It greatly improves work efficiency and plays an important role in the detection of the packaging industry.

In the packaging industry, industrial borescopes can be used to detect the internal conditions of various opaque bottles, bags, boxes, boxes and other packaging products that cannot be directly seen by human eyes or ordinary equipment. The images are displayed in real time and can be photographed. , video, marking and other means to further observe and analyze the defects.

When industrial borescopes inspect the surface of materials or components, visual inspection is the easiest way to observe the surface conditions of the inspected parts, such as cleanliness and corrosion. Visual inspection revealed some obvious defects such as cracks and corrosion pits. However, sometimes some parts of the component, such as narrow and curved channels, cannot be directly observed at all. In order to improve the visual inspection effect, an industrial borescope is required.

Industrial borescopes are cost-effective and value for money. Compared with human eye inspection, the efficiency is greatly improved, and it is an indispensable tool for the packaging industry.

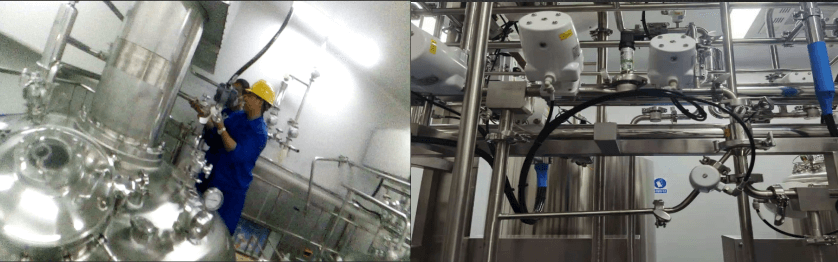

For the packaging industry, Yateks’ M series is especially recommended. This series of endoscopes has 8 advantages:

(1) 360°mechanical arbitrary steering, 180°bending——convenient, precise, and automatically lock the direction

(2) The insertion tube can be replaced, and the insertion tube of the corresponding length/diameter/lens specification can be replaced in different working scenarios, one machine with multiple functions, greatly reducing the cost of use

(3) Four-layer tungsten wire braiding of the insertion tube – high-density tungsten wire enhances the wear resistance and durability of the insertion tube, ensuring reliable inspection of castings or other metals with rough surfaces

(4) The insertion tube complies with IP67 standard – anti-corrosion, waterproof, dustproof, reliable inspection even in various harsh environments

(5) Lighting system – high-brightness LED packaging technology, the probe illuminance reaches 20,000lux, which is 200 times the illuminance of indoor fluorescent lamps, and the dynamic optimized light quantity can be applied to different working conditions

(6) 6 levels of high and low brightness manual adjustment – to adapt to different materials and environments

(7) 5x digital zoom – clear picture quality

(8) The body is small and light, and the hand-held ergonomic design is easy to carry