With the development of technology, more and more industries use helicopters as an efficient means of transport to improve work efficiency and respond to emergencies and other special operations, undertaking irreplaceable transport tasks in power transmission line inspection, wind power equipment monitoring, fire inspection, public security patrols, as well as aerial emergency rescue, offshore oil platform transport, and aerial sightseeing.

This time for the helicopter to do downtime inspection. Although the turboshaft engine of the helicopter is different from the large thrust aero-engine of ordinary civil airliners, the turboshaft engine does not have a large fan blade, the height of the compressor blade is less than 1/4 of the civil engine blade, the space of the combustion chamber is even narrower, and the turbine blade approaching the channel is so narrow that it only allows the detection equipment with an outer diameter of 4mm to enter. The unique internal structure brings great challenges to the inspection work, which requires the video borescope to have very strong guiding ability, bright illumination, clear dynamic and static picture quality, and good portability.

What parts are inspected in a helicopter?

Main inspection content: engine, combustion chamber turbine blades, combustion chamber, main reducer, lift bearing cage, travelling core gears and other major parts and components are inspected.

It mainly includes the following aspects:

- engine inspection: industrial borescopes are used for internal inspection of the engine, such as checking the ablation of the blades, the degree of edge defects of the blades, and the clogging of each nozzle and screen.

- Main Reducer: the wear, bite and crack of each tooth of the gears, whether there is obvious damage and deformation, the size of the gap between the gears, whether the bearings are damaged, loose or shifted, whether the cleanliness of the oil and the oil level are within the prescribed range, whether the lubrication is good, whether the oil is contaminated and leaked, and whether there is cavitation.

Customers’ demand for the use of borescopes

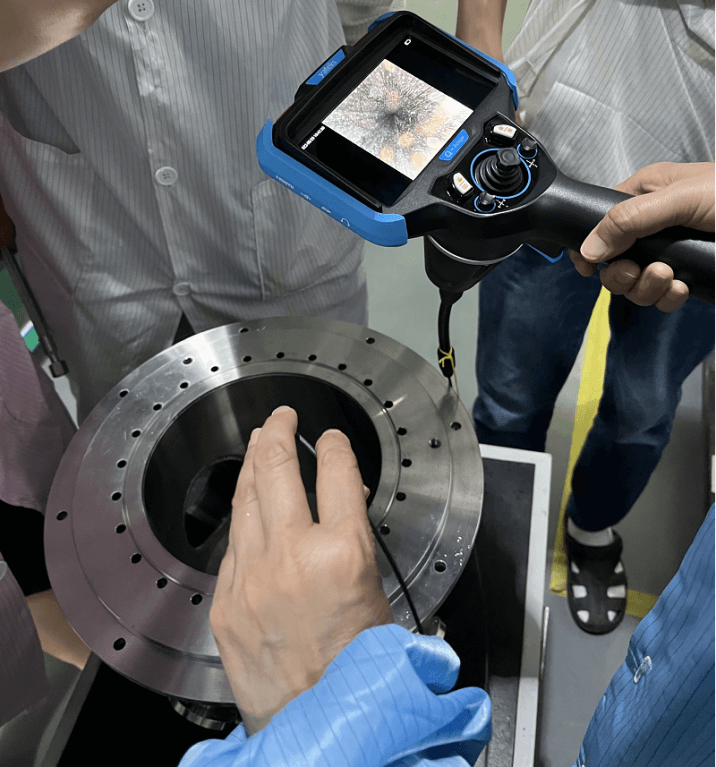

Customers need to hold portable borescopes for daily inspection and operation and maintenance work, and they have requirements for the clarity of the equipment, the sensitivity of the control, the stability of the product, and the weight of the equipment. The diameter is less than 4㎜, the length of the tube is 2 metres, the lens is ultra clear, the steering is electric, the fine adjustment locking, overload protection and other functions are available to assist the inspection needs, and the weight is not more than 3KG.

Solution

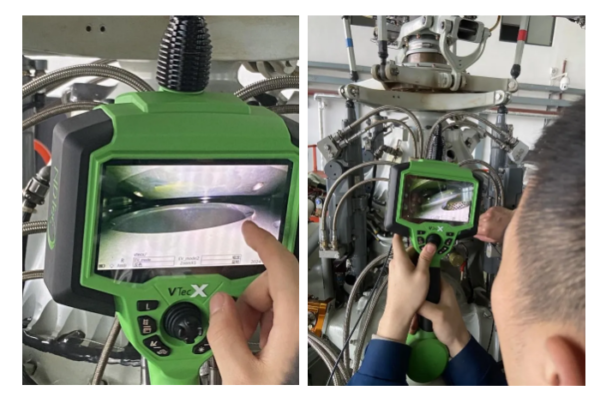

At the customer’s site, the industrial borescope models demonstrated in this demonstration were mainly three series, X series industrial borescope , N series industrial borescope and Q series industrial borescope. The borescope was used at the site to directly inspect the engine compartment of the helicopter because the space inside the helicopter’s engine was narrow, and the surface of the components was oil-contaminated, so it had high requirements for the lens’s sensitivity, the illumination of the light source, and the flexibility of the manipulation.

Inspection results

Customers are very satisfied with the detection effect of the three borescopes of Yateks, and give high evaluation on the clarity of imaging, sensitivity of the lens and the convenience of the equipment, and the engineers at the scene unanimously think that our domestic equipment can completely replace the imported brands in many aspects now, and give high evaluation to the X SERIES.