The core components of a diesel engine—injectors, plunger sleeves, and needle valve bodies—determine its power and efficiency. The internal channels of these precision components, ranging in size from a minimum of 5 mm to a maximum of 25 mm, are crucial for fuel atomization and pressure control. Micron-sized carbon deposits, nano-level leaks, and wear invisible to the naked eye can all significantly reduce engine performance and cause fuel consumption to soar.

What are the drawbacks of traditional inspection methods? Time-consuming disassembly, the risk of reassembly, and potential secondary damage. More importantly, defects hidden deep within winding channels and narrow cavities are often difficult to detect even after disassembly.

Yateks P Plus Industrial Borescope—Designed for Precision Small-Aperture Inspection

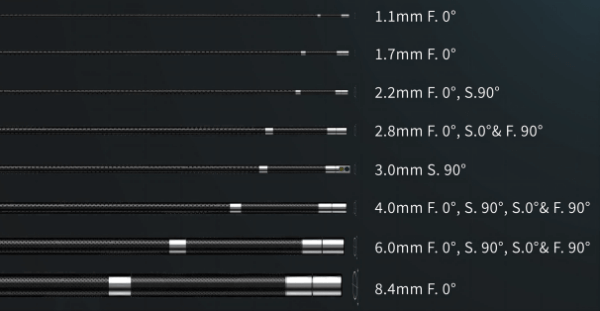

- Diameter Matching: Multiple probe diameter options, from 0.85 mm to 8.4 mm. Easily enters the 5 mm needle valve body orifice without forced insertion, avoiding scratching the precision internal surfaces.

- Flexible Operation, 360° Rotation Probe: The specially designed articulated probe allows for precise operation in confined spaces, easily reaching critical inspection points such as the curved oil passages within the plunger sleeve and the injector valve seat.

- Visual Revolution: “Ultra-Clear Vision” Within Small Orifices

- Two Million High-Definition Pixels: Even within the 5mm diameter of the needle valve body orifice, the high-resolution camera, combined with professional macroscopic optical design, clearly displays wear and corrosion on the needle valve sealing cone, capturing every minute detail.

Field Applications—How the Yatesks P Plus Industrial Borescope Solves Three Major Precision Component Inspection Challenges

-

Fuel Injector Nozzles—Carbon Deposits and Wear Assessment

Challenge: Nozzle clogging and needle valve sticking often begin with minute carbon deposits and microscopic wear.

Yateks P Plus Industrial Borescop Solution: Insert the probe into the fuel inlet of the injector to directly observe the internal nozzle and needle valve mating surfaces. High-definition images clearly assess the severity and distribution of carbon deposits and determine whether wear is within tolerance, providing a reliable basis for decisions on “cleaning/repair” versus “replacement.”

-

Plunger Sleeve – Inner Wall and Passage Inspection

Challenge: Scratches or corrosion on the inner wall of the plunger sleeve can directly lead to unstable fuel pressure and internal leaks.

Yateks P Plus Industrial Borescop Solution: Perform a comprehensive scan within the 25mm (or smaller) plunger sleeve bore to inspect the surface finish of the inner wall. A flexible probe can enter the inlet/return oil passages to inspect for machining burrs or abnormal wear, preventing fuel delivery problems caused by passage blockage.

-

Needle Valve Body – Sealing Surface and Seat Inspection

Challenge: Minor damage to the sealing cone surface can lead to dripping and poor atomization.

Yateks P Plus Industrial Borescop Solution: Precisely positioned within a minimum 5mm orifice of the needle valve body, focusing on the sealing cone. Superior imaging technology helps identify fatigue cracks and corrosion pitting invisible to the naked eye, ensuring rigorous quality control.

Part Three: What economic value does the Yatesks P Plus Industrial Borescope bring?

- From “Failure Prevention” to “Life Prediction”: By regularly tracking and recording microscopic defects, a component wear trend profile is established, enabling a shift from reactive maintenance to proactive predictive maintenance.

- From “Experience-Based Judgment” to “Data-Driven Decision Making”: Clear images serve as the technical basis for maintenance planning, avoiding disputes. Digital archiving of inspection reports provides core data for equipment health management.

- Maximizing Cost-Effectiveness: A single inspection accurately assesses component condition, avoiding unnecessary scrapping of slightly damaged and repairable parts and avoiding the installation of severely worn parts. Significantly reduces spare parts costs and the risk of secondary failures.

Which companies need the Yatesks P Plus Industrial Borescope?

- Diesel engine overhaul shops/remanufacturers: The Yatesks P Plus Industrial Borescope accurately assesses used parts, which is crucial for remanufacturing processes.

- Maintenance teams for marine, power plant, and railway equipment: Yatesks P Plus Industrial Borescope enables rapid, non-destructive testing of critical powertrain components, ensuring operational safety.

- Fuel injection pump/nozzle manufacturers and quality control departments: Yatesks P Plus Industrial Borescope implements rigorous factory quality control with “zero tolerance” for internal cavity defects.

For more information on Yatesks P Plus Industrial Borescope products, please contact us at [email protected]