In today’s fast-paced industrial landscape, non-destructive testing has become essential for maintaining operational efficiency and safety. As a powerful visual inspection tool, industrial endoscopes allow you to peer inside equipment and pipelines without disassembly, saving both time and resources. But with so many options available, how do you choose the right one for your specific needs? Here are 8 crucial factors to guide your selection process:

1. Define Your Inspection Requirements Clearly

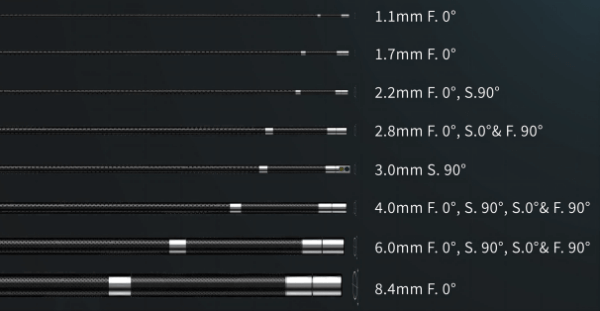

Start by analyzing your specific application needs. Consider the equipment type you’ll be inspecting, target areas, access hole diameters, required insertion length, and working environment. A well-defined requirement profile ensures you select the most suitable endoscope for your unique applications.

2. Image Clarity & Resolution: See Every Detail Matters

Superior image quality is fundamental for accurate defect detection. Modern endoscopes offer pixel options ranging from 40,000 to 5 million pixels for pipelines under 10mm diameter. Meanwhile, display resolution varies from 800×480 on 4.3-inch screens to ultra-high 1920×1200 on 7-inch displays. Higher resolution means better detection of minute defects and more reliable inspection results.

3. Operation Method: User Experience Counts

Choose between handheld portability and benchtop stability based on your operational needs. Consider the intuitiveness of the operating system and control layout – a user-friendly interface significantly enhances inspection efficiency and reduces operator training time.

4. Environmental Adaptation: Built for Challenging Conditions

Different environments demand specialized endoscopes. High-temperature settings require heat-resistant models, while corrosive environments need anti-corrosion capabilities. For radioactive areas, radiation-resistant endoscopes are essential. Select equipment that matches your specific working conditions.

5. Safety Compliance: Never Compromise

Ensure your chosen endoscope meets all relevant safety standards. In explosive atmospheres, explosion-proof certification is mandatory. Always follow manufacturer guidelines to guarantee operator safety and equipment reliability.

6. Brand Reputation & Service Support

Established brands typically offer better product quality, reliable performance, and comprehensive after-sales support. Choose manufacturers with proven track records and strong technical support capabilities.

7. Smart Investment: Balance Price and Value

While price is important, it shouldn’t be the sole deciding factor. Consider the total value proposition – including performance, durability, maintenance costs, and after-sales service. The right endoscope represents a long-term investment in your operational efficiency.

8. Comprehensive Comparison: Make an Informed Choice

Compare different models and brands to understand their unique features, advantages, and limitations. This thorough approach helps you identify the perfect match for your requirements.

Beyond the Basics: Advanced Functionality Matters

While these 8 factors cover the essentials, don’t overlook advanced functionalities that could significantly enhance your inspection capabilities. Basic photo and video recording might suffice for some applications, but if you require 3D measurement, automatic defect recognition, or specialized analysis features, ensure your chosen endoscope can deliver these advanced capabilities.

Partner with the Right Manufacturer

Engage in detailed discussions with potential suppliers about your specific needs. Understand their customization capabilities and technical expertise. A reliable manufacturer should offer comprehensive after-sales support, ensuring you can use your equipment with confidence long after purchase.

Choosing the right industrial endoscope is about finding the perfect balance between technical specifications, operational requirements, and long-term value. By considering these key factors, you’ll be equipped to make an informed decision that delivers lasting benefits to your organization.

Ready to find your ideal industrial endoscope solution? Contact our experts today for personalized consultation and discover how our cutting-edge technology can transform your inspection processes.